Introduction: Smarter, Faster, More Compact

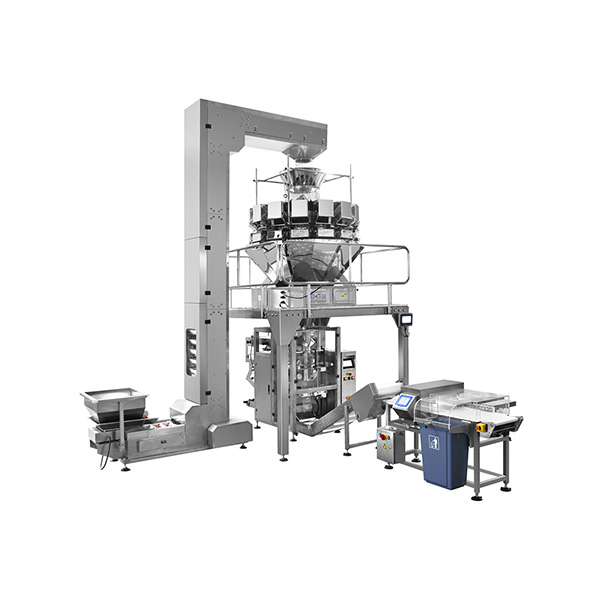

In today’s competitive manufacturing world, automation is not a luxury — it’s a necessity. A vertical packaging machine (also known as a Vertical Form-Fill-Seal machine or VFFS) integrates forming, filling, sealing, and cutting into one continuous process.

DGX’s Vertical Packaging Machine Series offers highly efficient, compact, and intelligent solutions for various industries — from food, snacks, and coffee to chemicals, hardware, and liquids.

What Is a Vertical Packaging Machine?

A Vertical Packaging Machine automatically forms film into a bag shape, fills it with product, and seals it — all in a vertical flow.

This system offers tremendous space efficiency, speed, and product versatility, making it one of the most widely used packaging solutions in the world.

Key Benefits

- Compact design: Ideal for workshops with limited floor area

- High output: up to 100 bags per minute, depending on product and model

- Low maintenance cost: Fewer moving parts than horizontal systems

- Flexible film options: Polyethylene (PE, including LEPE/LLDPE/HDPE), Polypropylene (PP), Polyester (PET), composite films, aluminum laminates, paper film

- Strong sealing performance: Leak-proof and durable seals

DGX Vertical Packaging Machine Series

DGX offers several models designed to meet different packaging requirements — from small sachets to large bags, and from powders to liquids.

Main Models

- Small Vertical Packaging Machine (Mini Type)– Compact body for granules, powders, and liquids

- VFFS Powder Packaging Machine– With auger filler for high-precision powder dosing

- VFFS Granule Packaging Machine– With volumetric cup or weighing system

- Liquid Vertical Packaging Machine– With pump filler for viscous or liquid materials

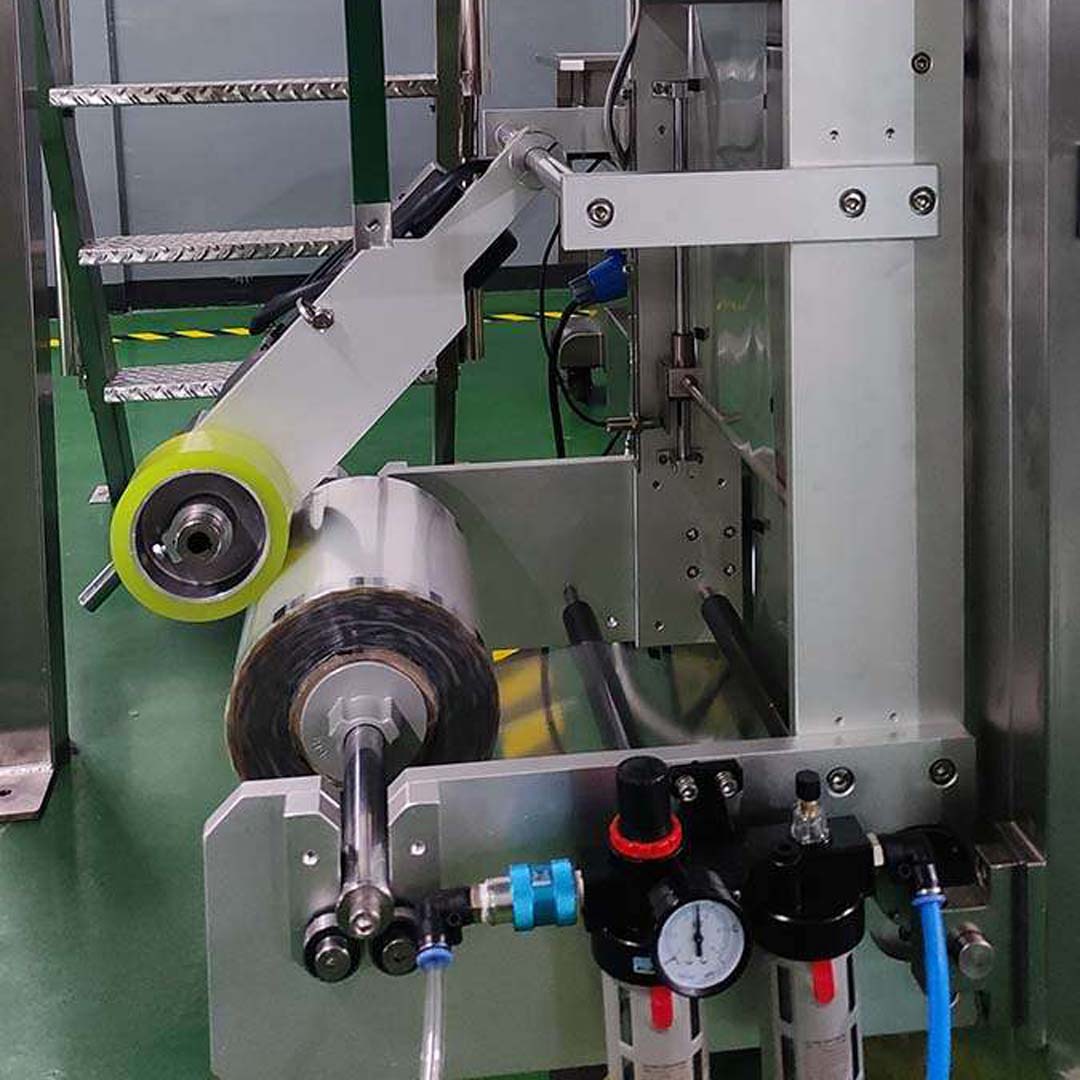

Standard Configuration

- PLC Control + Touch Screen Operation

Easy to operate, supports parameter memory, and automatically displays faults. - High-Precision Sensors

Guarantees stable film feeding and accurate sealing position. - Servo Motor System

Ensures smooth bag pulling and precise cutting. - Stainless Steel 304/316 Construction

Meets food hygiene standards, durable, and corrosion-resistant.

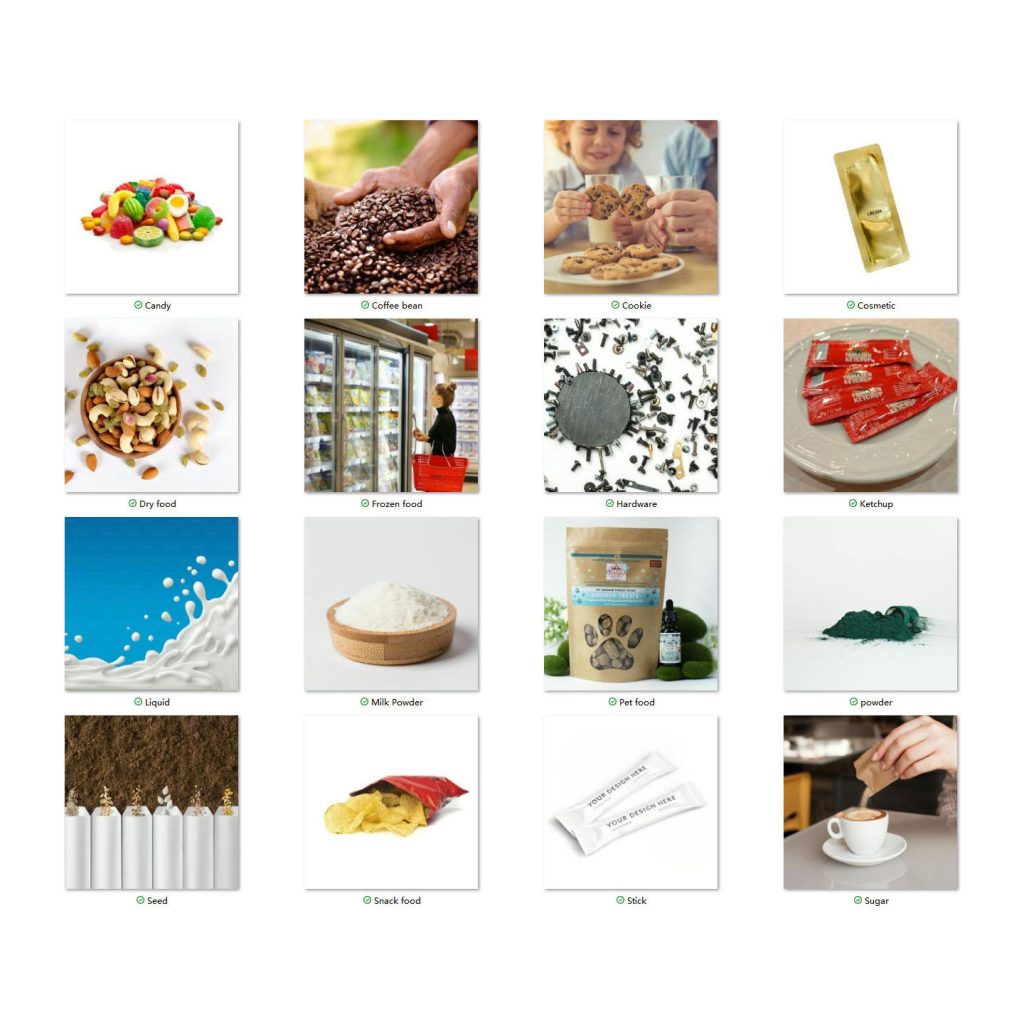

Application Range

DGX vertical packaging machines are designed for multi-industry and multi-product use, suitable for:

| Product Type | Example Products | Recommended Machine |

| Granules | Sugar, Oats, Coffee Beans, Mung Beans,

Lentils, Chickpeas, Rice, Hard Candies, Puffed Snacks, Salt, Seeds, Pet Food, Fertilizer |

Granule Vertical Packaging Machine |

| Powders | Milk Powder, Protein Powder, Instant Coffee,

Spices, Chili Powder, Tang (Powdered Drink), Curry Powder, Chemicals, Cosmetics, Flour, |

Powder Vertical Packaging Machine |

| Liquids & Paste | Sauce, Shampoo, Juice, Detergent, Oil, Vinegar,

Ketchup, Honey, Syrup, Salad Dressing, Mustard, Sriracha Sauce, Cream, Fabric Softener, Toilet Cleaner |

Liquid Vertical Packaging Machine |

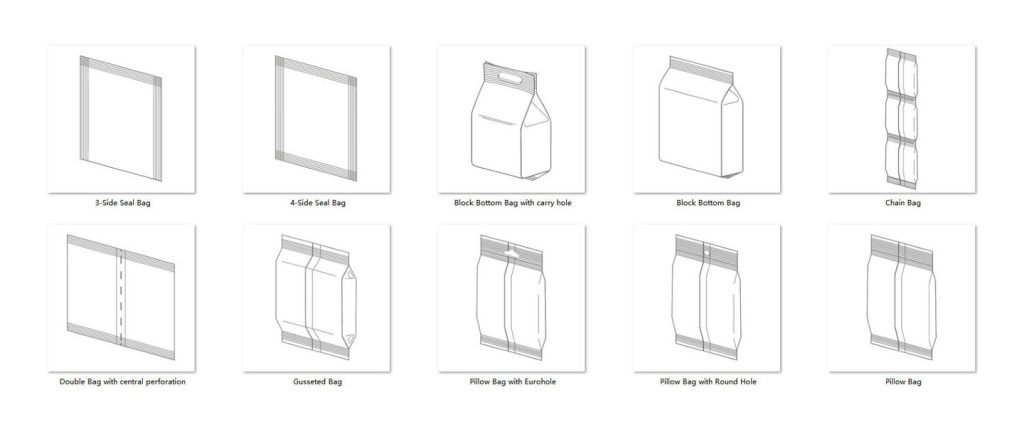

Bag Styles and Custom Options

DGX’s vertical machines can produce a wide range of bag types to fit your market and product needs:

- Pillow Bag

- 3-Side Seal Bag

- 4-Side Seal Bag

- Stick Pack

- Chain Bag / Linked Bag

- Gusseted Bag (for coffee or grains)

- Custom printing, tear notch, hanging hole, or zip-lock options can be integrated upon request.

Technical Highlights

| Feature | Description | Customer Benefit |

| PLC + HMI Control | Simple, visual interface | Easier setup & faster changeover |

| Film Tracking Sensor | Automatic color mark tracking | Reduced film waste |

| Adjustable Bag Length & Width | Servo controlled | Perfect fit for various bag sizes |

| Auto Error Detection | Faults shown on screen | Reduced downtime |

| 304/316 SS Frame | Food-grade structure | Clean & long-lasting performance |

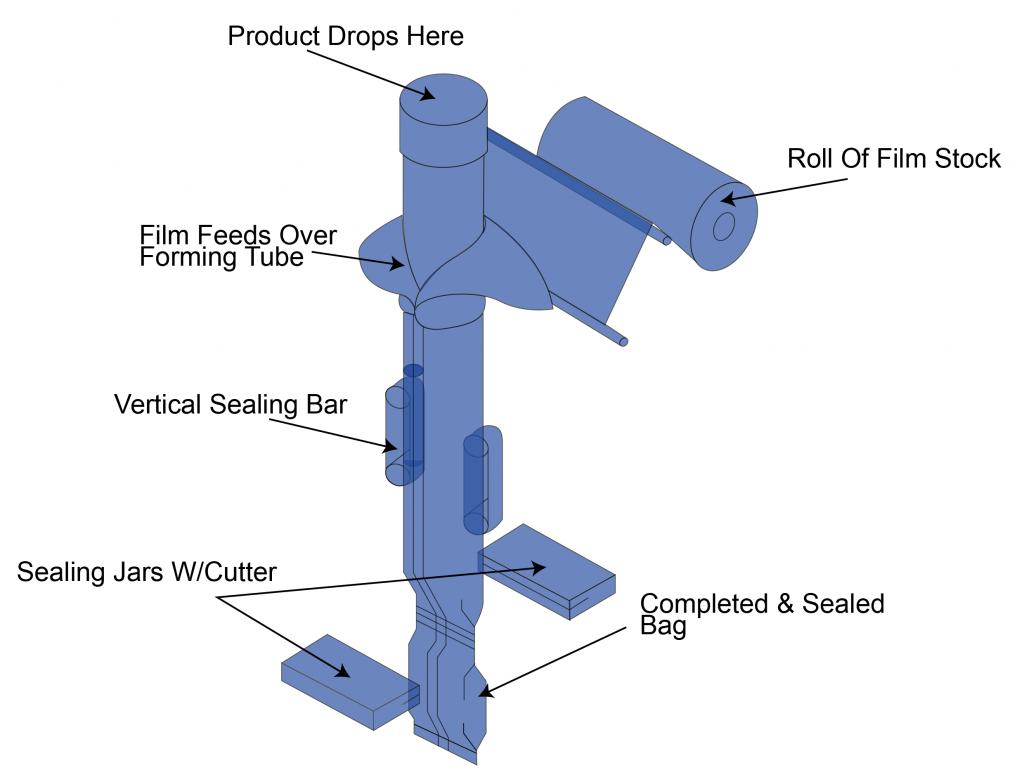

How a DGX Vertical Packaging Machine Works

- Film Unwinding– Film roll fed into forming tube

- Bag Forming– Film folded and sealed vertically

- Product Filling– Filler dispenses a set amount

- Sealing & Cutting– Horizontal sealing jaws close, then cut

- Finished Product Output– Completed bags exit conveyor

This streamlined workflow ensures consistency, hygiene, and efficiency across every production cycle.

Choosing the Right Vertical Packaging Machine

When selecting your model, consider:

- Product type(powder / granule / liquid)

- Bag size and style

- Target output (bags/min)

- Film material and thickness

- Hygiene level requirements(food-grade or industrial)

DGX’s engineers can provide custom recommendations and machine configurations tailored to your exact production goals.

After-Sales Support and Service

DGX ensures long-term performance with:

- Lifetime technical support via email/video

- Remote guidance for setup and training

- Spare parts are readily available

- Fast delivery: 7–15 days for standard models, 20–30 days for custom builds

Why Choose DGX Machinery

Professional Experience – More than 10 Years of experience in filling and packaging machine manufacturing for global clients

Reliable Quality – Strict QC process and CE-certified designs

Flexible Customization – Tailored designs for your packaging product line

Competitive Pricing – Excellent value for medium to large-scale factories

Global Reach – Exported to over 50 countries worldwide

Frequently Asked Questions (FAQ)

What types of products can be packed using DGX vertical machines?

They can pack powders, granules, liquids, and non-food items like screws or pet treats. DGX offers dedicated fillers for each product type.

What bag materials can be used?

The machine is compatible with PE, PP, PET, laminated film, and aluminum foil film. DGX engineers can help choose the best material for your product.

What is the delivery time?

Standard models are ready in 7–15 days, while customized machines require about 20–30 days.

Does DGX offer installation and training?

Absolutely. DGX provides remote video guidance and on-site support if required.

How do I maintain the machine?

Regularly clean the sealing area, check film alignment, and lubricate moving parts. DGX provides a full maintenance manual.

Get Your Packaging Solution Today

Whether you are in food, chemical, or daily-use product manufacturing, a DGX Vertical Packaging Machine gives you the speed, flexibility, and reliability needed for today’s competitive market.