The DGX BF Series Automatic Side Sealer is designed for high-speed, continuous packaging of various products using shrink film. Equipped with a servo-driven sealing system and photoelectric tracking, it ensures precise sealing lines, smooth operation, and excellent packaging appearance. Suitable for industries such as food, daily necessities, cosmetics, printing, and e-commerce logistics, this machine helps enterprises achieve efficient, automated, and cost-saving packaging solutions.

Continuous Side Sealing System: Enables uninterrupted packaging for products of unlimited length.

High Efficiency & Output: Speed up to 2,000 packs/hour. Maximize your production line throughput.

Intelligent Auto-Adjustment: auto-adjusts for any size. Seals and cuts perfectly with smart photo-eye sensing.

Energy-Efficient Design: Uses optimized heat systems to reduce power consumption.

Compatible with Shrink Tunnel: Delivers tight and attractive packaging results.

Integrated Scrap Management: Automatic waste collection. Keeps the line clean with a motorized rewind system.

Robust & Stable Design: Built to last. Premium steel and precision components ensure long-term durability.

The BF Series Side Sealer is more than a Packaging Machine; it’s a strategic partner in optimizing your packaging operations. Built to withstand the rigors of industrial use, it delivers exceptional performance where it matters most.

The DGX Continuous Shrink Wrapping Machine adopts a horizontal continuous sealing structure with automatic feeding, film wrapping, sealing, and cutting functions. It can be used with a shrink tunnel to form a fully automated packaging line. The servo-driven cutter ensures consistent sealing quality even at high speeds.

This machine is ideal for medium to large-scale packaging operations requiring flexibility and efficiency. It reduces manual work, prevents packaging errors, and improves production capacity and consistency, helping manufacturers lower costs and enhance brand image.

| Model | BF-450 | BF-550 | BF-650 | BF-750 | BF-850 | BF-950 | BF-1050 |

| Packing Size(Max.) | W+H≤400mm H≤200mm |

W+H≤500mm H≤200mm |

W+H≤600mm H≤200mm |

W+H≤700mm H≤200mm |

W+H≤800mm H≤200mm |

W+H≤900mm H≤250mm |

W+H≤1000mm H≤250mm |

| Capacity | 15-30 Packages/min(depands on products) | ||||||

| Power Supply | AC220V(1p) 50/60Hz(Special Voltages Available Upon Request) | ||||||

| Air Pressure | 0.5MPa | ||||||

| Power | 1.35kW | 1.5kW | 1.5kW | 2kW | 2kW | 2kW | 2.5kW |

| Dimension | 1650x800x1460mm | 1810x980x1460mm | 2010x1080x1460mm | 2310x1280x1460mm | 2410x1380x1460mm | 2510x1480x1460mm | 2710x1680x1460mm |

| Weight | 300kg | 350kg | 400kg | 450kg | 550kg | 650kg | 750kg |

Contact our sales experts for a tailored side seal packaging solution to boost your output now.

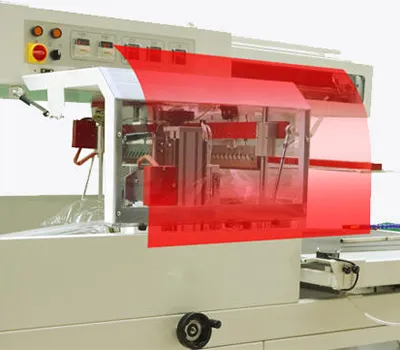

Operate with confidence with a transparent safety guard that provides full visibility while keeping hands safely away from moving parts.

Our intelligent conveyor system self-adjusts its feed length for minimal errors and reduced operator workload.

Achieve wrinkle-free, tight wraps with integrated air nozzles that ensure a smooth finish on every package.

Ensure precise product positioning and timing with photoelectric sensors for effortless set-and-forget packaging efficiency.

Experience flawless seals with DuPont Teflon®-coated blades that resist fouling, smoke, and weak seals for reliable performance.

Streamline your operation with automatic scrap film collection, ensuring a tidy, tangle-free workspace and reduced manual handling.

Dive Deeper into the BF Series Superiority

Explore our technical specifications and case studies to see how we deliver. We offer:

Customized Configuration: Flexible models and options to match your specific product materials and output requirements.

Global Support Network: Our professional service team ensures quick installation, commissioning, and ongoing technical support.

Broad Industry Application: Ideal for food & beverage, cosmetics, household goods, printed materials, textiles, and more.

Get a Customized Packaging Machine Solution!