FL-C Vertical PE Film Sealing Machine

The FL-C Series Vertical PE Film Sealing Machine is designed for efficient and continuous packaging operations. It adopts a vertical sealing structure that delivers precise sealing performance and stable packaging quality. Equipped with automatic film feeding, adjustable sealing temperature, and high-speed control, this system ensures consistent sealing for PE film materials across various packaging lines. Ideal for industrial users seeking automation and reliability in high-throughput packaging processes.

Vertical Sealing Design: Ensures smooth, wrinkle-free sealing, maintaining product aesthetics.

High-Speed Servo Control: Guarantees precise film feeding and cutting synchronization.

PE Film Compatibility: Optimized for PE film sealing with excellent heat balance and durability.

Adjustable Sealing Temperature: Adapts to various film thicknesses and materials for flexible use.

Easy Integration into Packaging Lines: Compact vertical design fits seamlessly into automated production systems.

Vertical PE Film Sealing Machine Description

The Vertical PE Film Sealing Machine delivers continuous, high-speed sealing for PE film materials, making it ideal for industrial packaging lines. Its vertical sealing system ensures precise temperature control and uniform seal quality, even during long production runs.

The machine can be easily integrated with automatic feeding, labeling, or shrink wrapping systems, enhancing production efficiency and minimizing manual operation. With its durable construction and intelligent interface, it provides long-term performance stability and reduced maintenance costs.

Learn more about our Vertical PE Film Sealing Machine and explore how it can improve your packaging line efficiency.

Product Advantages

The Vertical PE Film Sealing Machine stands out with its intelligent temperature control system, high structural strength, and energy-efficient design.

It uses PID temperature control technology for rapid heat response, ensuring consistent sealing quality and minimizing defective rates.

Its robust steel body provides superior durability and vibration resistance, extending machine life while reducing maintenance costs.

The intuitive touch-screen interface makes operation straightforward and reduces training time for operators.

Additionally, the modular system layout allows flexible configuration with various feeding, conveying, or shrink modules to meet different packaging requirements.

Energy-saving components optimize heating performance and power usage, resulting in lower operational costs and better energy efficiency for industrial users.

Vertical PE Film Sealing Machine Technical Data Sheet

| Model | FL-450C | FL-550C |

| Packing Size(Max.) | L+Hx1.5≤500mm W+Hx1.5≤400mm H≤150mm | L+Hx1.5≤600mm W+Hx1.5≤500mm H≤150mm |

| Capacity | 15-30 Packages/min(depands on products) | |

| Power Supply | AC220V(1p) 50/60Hz(Special Voltages Available Upon Request) | |

| Air Supply | 0.6-0.8MPa | |

| Shrink Film | POF/PE (For specific films or anti-static varieties, please consult with our technical team) | |

| Power | 1.5kW | 2.2Kw |

| Dimension | 1650x880x1450mm | 1950x1000x1450mm |

| Weight | 280kg | 350kg |

Get a Quote for Vertical PE Film Sealing Machine

Contact us today to upgrade your packaging line efficiency and sealing quality!

Vertical PE Film Sealing Machine Applications

- E-commerce and logistics packaging

- Industrial product bundling

- Food and beverage outer wrapping

- Daily chemical and hardware packaging

- Printing and stationery industries

Vertical Sealing Machine Detail Display

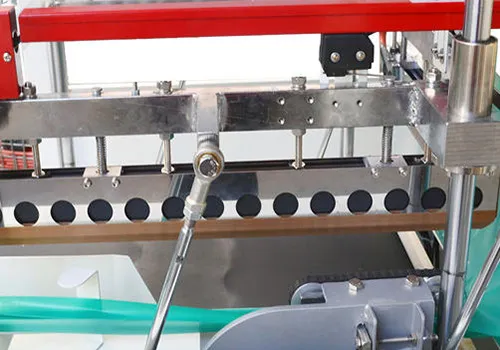

Minimalist design for effortless operation and rapid proficiency

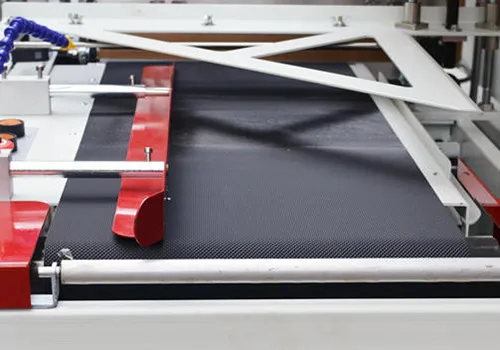

Premium coated alloy construction ensures extended service life.

An automatic safety mechanism prevents misfeeding and product damage.

Adjustable positioning to accommodate varying product dimensions.

Precisely controls triangular guide plate elevation for optimal product alignment.

Delivers strong load capacity and rapid acceleration.

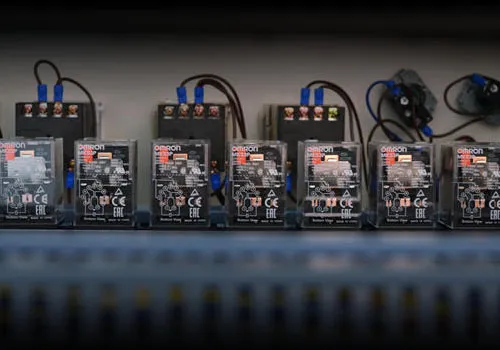

Omron relay components ensuring stable performance and operational reliability.

Precision photoelectric detection for accurate package positioning.

Vertical blade action ensures stronger seals and superior finish quality.

It is optimized for PE film but can also handle other poly-based materials with adjustable temperature settings.

Yes, it can be connected with automatic feeders, labeling units, and shrink tunnels to form a complete automated line.

Depending on model and film type, the sealing speed ranges from 20 to 60 packs per minute.

The machine uses a PID temperature controller for precise and stable heat management, ensuring uniform sealing results.

Routine inspection of heating elements and cleaning of sealing surfaces is recommended. The modular design allows for easy maintenance and part replacement.

More about FL-C Series Vertical PE Film Sealing Machine

The DGX FL-C Series Vertical PE Film Sealing Machine represents the next step in automated film packaging. Designed with both efficiency and reliability in mind, it supports continuous operation under demanding industrial conditions. Its vertical sealing mechanism is especially suitable for large-format packaging or products requiring tight, clean seals.

With strong mechanical stability, energy-saving performance, and easy maintenance, this system is a preferred choice for manufacturers upgrading to automated packaging solutions.