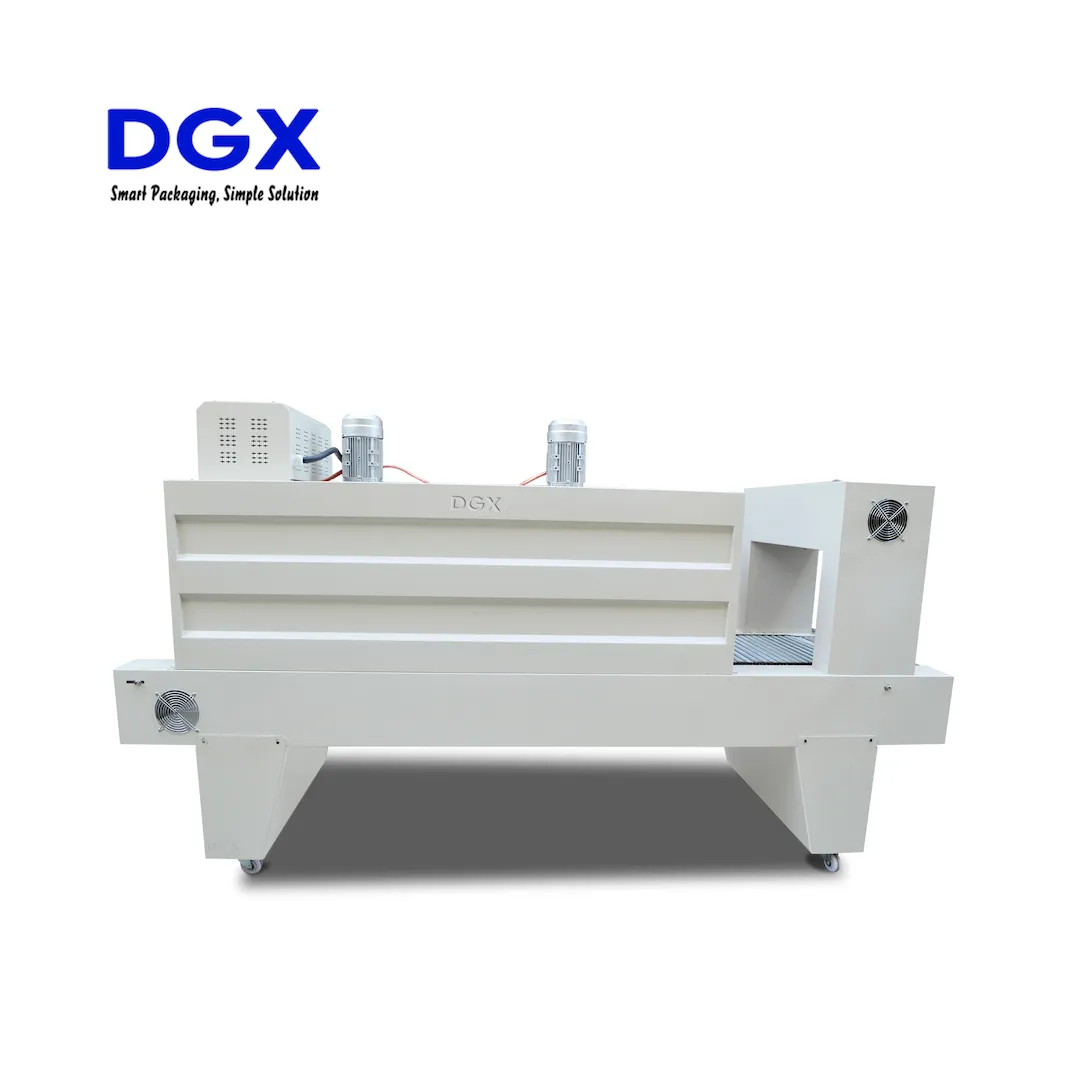

RSE-A Forced Air PE Film Heat Shrink Tunnel

High-Performance Jet-Air Shrink Tunnel for PE Film Packaging

The RSE-A Series Forced Air PE Film Heat Shrink Tunnel is a high-efficiency packaging solution designed for industrial users who demand precision, consistency, and energy savings.

By using a powerful jet-air circulation system, the tunnel ensures uniform heat distribution, excellent shrink finish, and stable performance under continuous operation.

It is the preferred solution for PE film shrink packaging in beverage, logistics, household, and construction industries where durability and appearance both matter.

Powerful Forced Air System – Delivers consistent and uniform heat distribution for perfect shrink results.

PE Film Optimized Design – Tailored for thick PE shrink films with enhanced air pressure and temperature balance.

Energy-Efficient Heating – Reduces power consumption while maintaining constant temperature.

Industrial-Grade Durability – Heavy-duty structure ensures long service life under continuous operation.

Flexible Integration – Compatible with sleeve wrappers, L-bar sealers, and automatic packaging lines.

RSE-A Series Forced Air PE Film Heat Shrink Tunnel Description

Precision Shrinking with Forced Air Circulation

The RSE-A Series Forced Air PE Film Heat Shrink Tunnel uses a high-pressure jet-air system with adjustable air ducts to ensure precise temperature control and even airflow distribution.

Every product passes through a uniform heat zone, resulting in tight, clean, and visually appealing packaging.

Customer Value:

- Perfect shrink finish and brand presentation.

- Reduced waste and fewer rejects.

- Continuous, stable performance in demanding lines.

Specially Optimized for PE Film

Unlike PVC or POF tunnels, the RSE-A Series is built specifically for PE film shrink packaging.

Enhanced temperature range and airflow pressure make it suitable for thick, heavy-duty film and large-format products.

Customer Value:

- Reliable shrink for all PE film thicknesses.

- Secure bundling for beverages, construction materials, and logistics packaging.

- Lower risk of film breakage or uneven shrink marks.

Energy-Efficient Heating and Smart Control

Equipped with intelligent PID temperature controllers, the RSE-A Series automatically balances power output to maintain precise temperature.

Dual-layer insulation keeps heat inside the chamber, lowering operating costs and energy use.

Customer Value:

- Reduced power consumption.

- Consistent temperature for repeatable shrink results.

- Extended heater life and fewer maintenance stops.

Heavy-Duty Design for Continuous Operation

The tunnel body is built from reinforced steel with a heat-resistant chain conveyor, ensuring durability even under constant heat exposure.

This robust construction allows continuous 24-hour production without deformation or performance loss.

Customer Value:

- Reliable long-term operation.

- Less downtime and lower maintenance costs.

- Improved total equipment efficiency (OEE).

Seamless Integration into Packaging Systems

Thanks to its modular structure, the RSE-A Series can easily integrate into automatic sleeve wrapping systems or L-Bar sealing machines.

All parameters—conveyor speed, air pressure, and temperature zones—can be customized to fit your packaging line.

Customer Value:

- Fully automated shrink wrapping system.

- Easy upgrade path for existing production lines.

- Reduced labor and faster throughput.

Customer Benefits at a Glance

- Consistent, professional packaging quality

- Energy savings up to 27%

- Designed for PE film thickness 40 – 120 μm

- Reliable 24/7 industrial performance

- Easy integration with existing lines

- Minimal maintenance & low running cost

Technical Highlights

- Adjustable air volume and direction for precise heat distribution.

- Independent temperature control zones for energy optimization(optional)

- Stainless-steel heating elements for rapid response.

- Conveyor speed control (variable frequency).

- Optional Teflon mesh belt and touch-screen controller.

Forced Air PE Film Heat Shrink Tunnel Technical Specification

| Model | RSE-5040A | RSE-6040A | RSE-7050A | RSE-8060A | RSE-15040A |

| Heat Tunnel Size | 1500x500x400mm | 1800x600x400mm | 1800x700x500mm | 1800x800x600mm | 3000x1500x400mm |

| Converyor Speed | 0-15m/min(depands on products) | ||||

| Converyor Loading | <35kg (Special weight customizable) | ||||

| Power Supply | AC380V(3p) 50Hz (Special Voltages Available Upon Request) | ||||

| Shrink Film | PE, POF, PVC, PP | ||||

| Power | 20kW | 24kW | 28kW | 32kW | 40kW |

| Dimension | 2500x740x1500mm | 2800x840x1600mm | 2800x940x1700mm | 2800x1040x1800mm | 5000x1850x1850mm |

| Weight | 290kg | 340kg | 390kg | 450kg | 1800kg |

Get the Perfect Shrink Solution for Your Packaging Line

Contact us today for a tailored PE film shrink tunnel solution that boosts your production efficiency!

Forced Air PE Film Heat Shrink Tunnel Applications

Designed specifically to solve the packaging challenges of high-value, heavy, and fragile products, it provides an irreplaceable ultimate solution. It protects not only the product, but also the company’s reputation and the trust of its customers.

Beverage Packaging – Perfect for bottled water, soft drinks, and beer multipacks.

Logistics & E-commerce – Shrink-wrapping parcels and cartons for protection and stability.

Building Materials – Suitable for tile, flooring, or insulation film packaging.

Household & Consumer Goods – For multi-pack detergents, tissues, or daily products.

Industrial Products – Wrapping large machine parts and spare components.

RSE-A Forced Air PE Film Heat Shrink Tunnel Detail Display

Digital temperature control with intuitive parameter setting enables one-touch operation, streamlining workflow management while ensuring consistently efficient output and user-friendly performance.

Stainless steel heating elements provide continuous thermal output, automatically activating below set temperature and shutting off when reached to ensure consistency while minimizing energy consumption.

Engineered to deliver substantial load capacity and exceptionally smooth conveyance, this motor guarantees stable operation under heavy-duty conditions with minimal vibration or speed fluctuation.

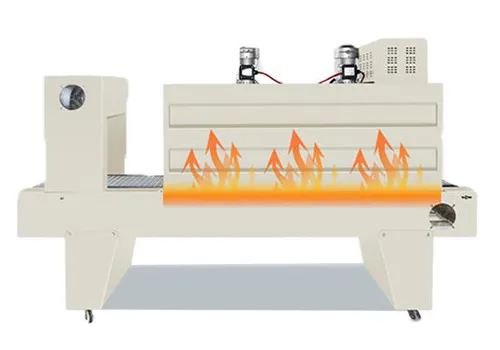

Stable metal tubular heaters combined with internal hot air circulation guarantee uniform heat distribution across various shrink films, resulting in professional and aesthetically pleasing packaging finishes.

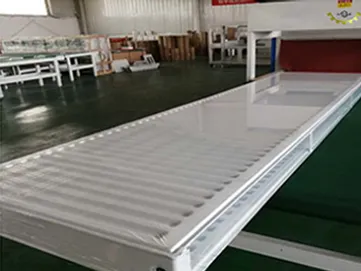

Its smooth-transfer design enhances packaging presentation while maintaining reliable performance that effectively boosts operational efficiency across diverse production environments.

Dual heavy-duty fans deliver powerful airflow for rapid heating and uniform shrinkage, ensuring aesthetically consistent results across various packaging materials and product geometries.

The tunnel size, conveyor height, and inlet width can all be customized according to your product dimensions.

The forced air heat circulation system evenly distributes hot air around the product surface, ensuring consistent shrinkage and a smooth finish without wrinkles or bubbles. This results in more professional-looking packaging for bottled, boxed, or multipack products.

Yes. The RSE-A Series allows seamless integration with L-bar sealers, vertical sealer, sleeve wrappers, and automatic conveyors to form a complete shrink packaging system.

Absolutely. The PID intelligent temperature controller provides precise temperature adjustment and real-time feedback, ensuring stable shrink performance during long-hour operation.

Thanks to its insulated chamber design and efficient airflow structure, the RSE-A Series can reduce energy consumption by up to 27%, making it one of the most energy-saving shrink tunnels for PE film applications.

Yes. We offer customized options for tunnel length, number of heating zones, airflow configuration, and conveyor width to fit various product sizes and production speeds.

The RSE-A is equipped with over-temperature protection, emergency stop switches, and cool-touch exterior panels, ensuring safety during high-temperature operation.

Typically 5–8 years with regular maintenance, even under continuous industrial operation.

More Product Details — RSE-A Series Forced Air PE Film Heat Shrink Tunnel

Advanced Airflow Dynamics for Perfect Shrink Balance

Unlike traditional shrink tunnels, the RSE-A Series is engineered with a balanced forced-air circulation system that directs airflow precisely around the product’s surface.

By controlling air pressure and distribution, it ensures uniform heat exposure, preventing film bubbles or partial shrinkage.

This makes it an ideal choice for PE film shrink packaging lines requiring consistent sealing quality and aesthetic presentation.

Optimized Tunnel Chamber Design for Energy Efficiency

The tunnel chamber is designed with multi-layer thermal insulation and a streamlined internal structure, reducing heat loss and improving thermal stability.

Combined with smart temperature management, the system achieves up to 27% energy savings compared to conventional PE film shrink tunnels.

Intelligent System Integration

The RSE-A Series supports interface compatibility with upstream sealing or wrapping systems.

It can be seamlessly integrated into automatic shrink wrapping lines, allowing synchronized operation and centralized control for higher productivity.

Enhanced Conveyor System for Heavy and Fragile Products

Equipped with a high-strength chain conveyor and stainless steel mesh belt, the tunnel ensures stable transport even for heavy or fragile items.

Speed is adjustable via a variable frequency drive, optimizing shrink results for different product sizes and film thicknesses.

Designed for Continuous Operation and Durability

All internal components are made from heat-resistant stainless steel and high-durability insulation materials, ensuring consistent performance during 24/7 operation.

This makes the machine highly reliable for industrial shrink packaging systems with continuous production schedules.

Sustainability and Green Packaging Focus

RSE-A helps factories move toward energy-efficient and sustainable packaging by minimizing waste and power consumption.

It supports eco-friendly PE film materials, which are recyclable and compliant with green manufacturing standards.