Our AS1000B Automatic Liquid Packaging Machine is a state-of-the-art solution designed for high-speed, accurate, and hygienic liquid packaging. Featuring an advanced cursor tracking system and a stepper motor film puller, it ensures perfect film alignment and tight, consistent seals, making it an essential tool for production lines requiring efficiency and precision.

Key Features:

- Advanced Cursor Tracking System

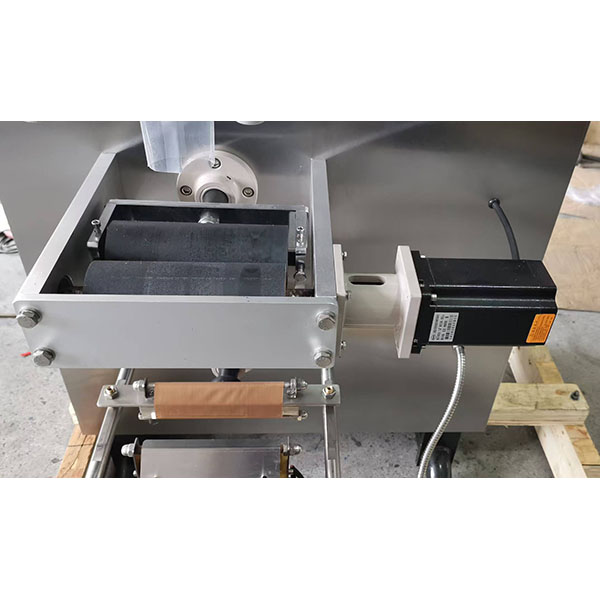

Detects registration marks on printed films for precise cutting and accurate brand positioning. - Stepper Motor Film Puller

Smooth and stable film feeding mechanism that reduces waste and ensures uniform bag size. - Durable Stainless Steel Structure

Built with food-grade materials for long-lasting performance and easy cleaning.

Built for Flexibility & Scalability:

- Modular Design: Easy to maintain and adjust for various pouch sizes and product types.

- User-Friendly Control Panel: Intuitive touch screen allows fast setup and operation adjustments.

- Flexible Production: Handles different film materials and is perfect for high-speed beverage packaging.

Ideal Applications:

- Bag Water

Ensures leak-free, hygienic sealing for pure water and flavored waters. - Juices & Energy Drinks

Perfect for juices, vitamin waters, and other functional beverages requiring precise packaging. - Co-Packing & OEM Beverage Services

Provides flexibility for contract packaging providers with minimal setup time.

How It Benefits Your Business:

- Reduce Material Waste: Advanced tracking and stepper motor system minimize film waste.

- Increase Efficiency: Streamline production with high-speed, consistent output.

- Improve Product Quality: Achieve professional, uniform packaging for a superior brand image.