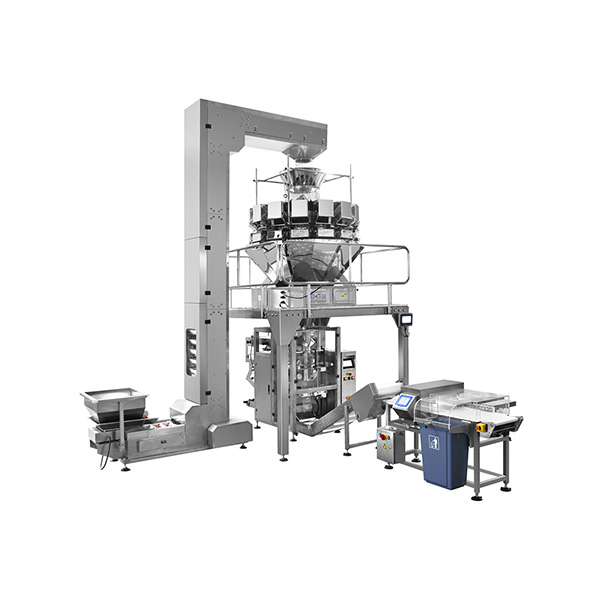

Product Overview

The DGX Automatic Vertical Packaging Line is a highly efficient, fully automated production line designed for granular, piece, nut, candy, puffed snack, dried fruit, coffee beans, seasoning, seeds, and small items.

The line integrates a vertical form-fill-seal (VFFS) machine, multihead weigher, Z-type elevator, working platform, finished product conveyor, metal detector, and checkweigher into a single, seamless system covering the entire process from material feeding, precise weighing, bag forming, filling, sealing, to product inspection, rejection of defective packages, and conveying.

Key Advantages:

- High Automation: Fully synchronized system reduces manual intervention and ensures continuous operation.

- High Efficiency: Combination of high-speed weighing and packaging ensures maximum throughput.

- Stable Operation: Modular design and precise integration minimize downtime and maintain production consistency.

- Multi-Spec Compatibility: Supports multiple bag types and sizes, adaptable to different products.

- Safety and Quality Assurance: Equipped with metal detection and checkweighing systems to guarantee product safety and compliance.

Line Modules, Functions & Benefits

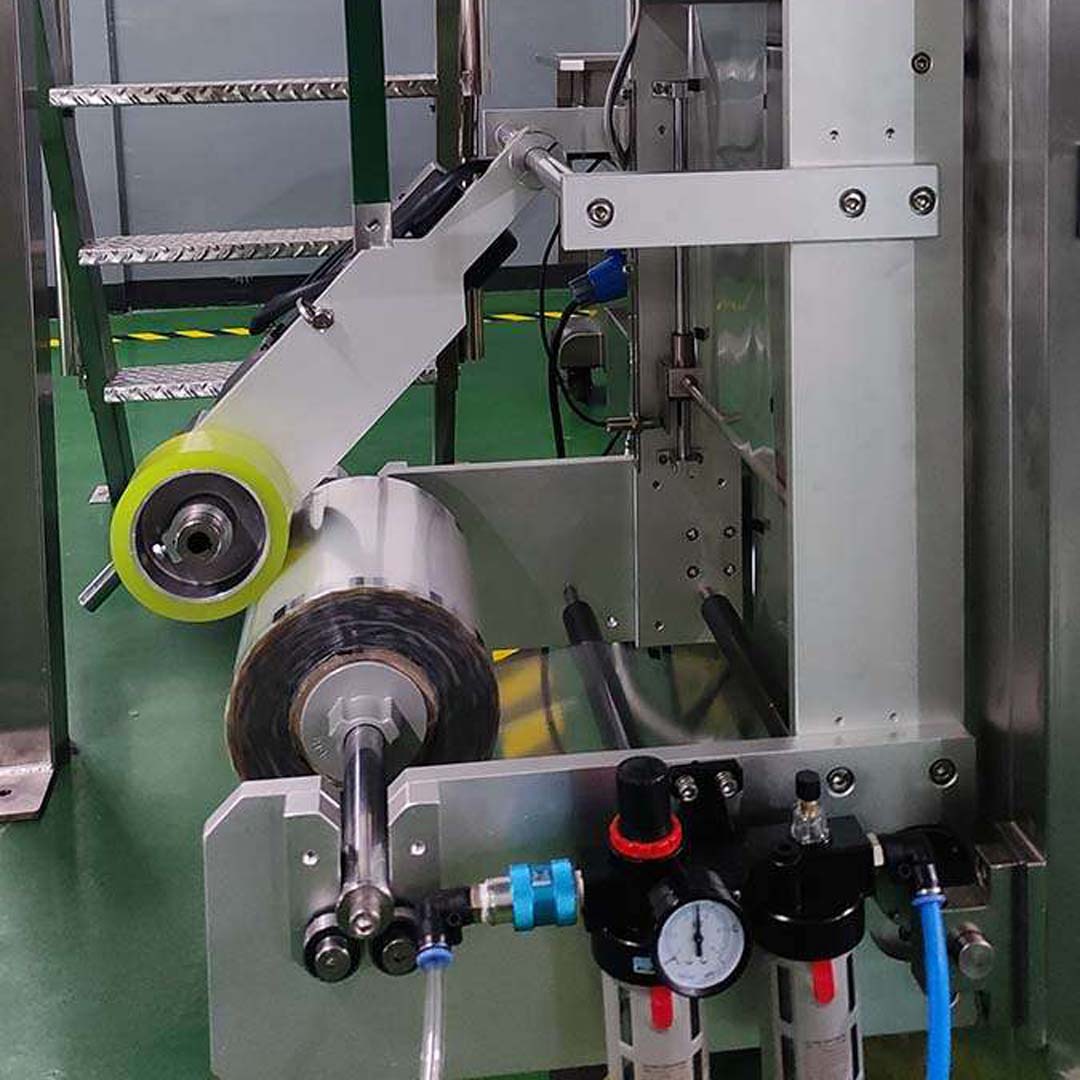

1. Vertical Form Fill Seal Machine (VFFS Machine)

The VFFS Machine serves as the core of the line, performing vertical bag forming, filling, and sealing. Its compact design allows high-speed operation and consistent packaging quality, saving floor space and reducing manual intervention.

Function: Performs vertical bag forming, filling, and sealing, suitable for various packaging materials and bag types.

Advantages:

- High-speed bag forming and sealing improve production efficiency.

- Compact design saves workshop space.

- Fully automated operation for easy maintenance.

Customer Benefits: Significantly increases output and packaging consistency while reducing labor costs.

2. Multihead Weigher

The Multihead Weigher provides high-speed, precision weighing for granular and small items. Its multiple heads ensure accurate measurement and minimize material waste, while enabling the line to handle various product sizes efficiently.

Function: High-speed and precise weighing for granular, flake, and small-sized products.

Advantages:

- Multi-head weighing improves accuracy.

- Quick adjustment for different product specifications.

- High-speed performance suitable for mass production.

Customer Benefits: Minimizes material waste, ensures pack weight accuracy, and maintains consistent product quality.

3. Z-Type Elevator

The Z-Type Elevator enables smooth vertical transport of materials to the packaging machine, ensuring a continuous supply even at high production volumes. Its design prevents product damage and supports a wide range of granular and small piece materials.

Function: Vertically transports materials to the packaging machine, ensuring continuous feeding.

Advantages:

- Steep-angle design for efficient bulk material conveying.

- Gentle transport minimizes product breakage.

- Compatible with fragile or slippery granular materials.

Customer Benefits: Maintains continuous machine operation and improves production efficiency.

4. Working Platform

The Working Platform stabilizes the combination of the multihead weigher and packaging machine, providing safe operation and convenient access for maintenance and cleaning.

Function: Provides stable support for the multihead weigher and packaging machine, ensuring safe operation.

Advantages:

- Enhances overall line stability and operational safety.

- Facilitates maintenance and cleaning access.

Customer Benefits: Improves safety and maintenance efficiency while reducing unexpected downtime.

5. Finished Product Conveyor

The Finished Product Conveyor automatically transports packaged products to downstream processes, such as boxing or warehousing, improving workflow efficiency and reducing labor costs.

Function: Automatically transports packaged products to the next production stage.

Advantages:

- It can be integrated with downstream equipment such as case packers, palletizers, or warehouse systems.

- Reduces manual handling and saves labor.

Customer Benefits: Boosts overall line productivity and lowers operating costs.

6. Metal Detector

The Metal Detector ensures food safety by detecting any metal contaminants in the finished products. Coupled with the Checkweigher, which automatically rejects over- or under-weight packages, the line maintains consistent product quality and compliance with international standards.

Function: Detects metallic contaminants within packaged products.

Advantages:

- High sensitivity for detecting various metal types.

- Automatically rejects contaminated products.

Customer Benefits: Ensures food safety, complies with international standards, and enhances customer trust.

7. Checkweigher

The Checkweigher guarantees accurate weight control for every packaged product, ensuring consistency and compliance with industry standards. Working seamlessly with the Metal Detector, it automatically identifies and rejects any package that falls outside the set weight range, helping maintain a high-quality production line.

Function:

Measures the weight of finished packages in real time and removes overweight or underweight items automatically.

Advantages:

- High-precision weighing with rapid response speed.

- Real-time monitoring and data recording for quality tracking and reporting.

- Seamless integration with upstream and downstream equipment for continuous operation.

Customer Benefits:

Improves product quality consistency, minimizes manual inspection, and enhances production efficiency while maintaining compliance with international packaging standards.

8. Rotary Collecting Table

The Rotary Collecting Table serves as the final stage of the packaging line, collecting finished products in an orderly manner for easy packing, inspection, or manual handling. It’s an efficient solution to streamline workflow and maintain continuous production without interruption.

Function:

Automatically receives and accumulates packaged products from the conveyor, enabling convenient product collection and sorting.

Advantages:

- Adjustable speed control to match line output.

- Smooth and stable rotation prevents product damage.

- Stainless steel construction for durability and hygienic operation.

Customer Benefits:

Simplifies product collection and packing processes, reduces manual workload, and improves overall line efficiency and organization.

All modules are integrated through a full-line automation system using PLC or industrial control technology. This synchronization allows remote monitoring, automatic adjustments, and error alerts, ensuring the line operates continuously with minimal downtime.

Finally, the entire line is highly flexible, capable of handling various bag types, including pillow bags, gusset bags, block bottom bags, and self-standing zip-lock bags, making it suitable for a wide range of products and packaging specifications.

| Module | Function | Customer Benefits |

| VFFS Machine | Vertical bag forming, filling, and sealing | Compact footprint, fast operation, consistent packaging quality |

| Multihead Weigher | High-speed, multihead precision weighing for granular and small items | Accurate measurement, reduced material waste, consistent product weight |

| Z-Type Elevator | Vertical transport of materials to the packaging machine | Continuous supply for high-volume production, smooth material handling |

| Working Platform | Stable support for weighing and packaging modules | Safe operation and easy maintenance |

| Finished Product Conveyor | Automatic transfer of packaged products to downstream processes | Enhances overall production efficiency, reduces labor costs |

| Metal Detector | Detects metal contaminants in finished products | Ensures food safety and brand reliability |

| Checkweigher | Automatic rejection of over- or under-weight packages | Improves product quality compliance, reduces manual inspection costs |

| Full Line Automation | Synchronized operation of all modules via PLC or industrial control system | Reduces human error, allows remote monitoring, optimizes production efficiency |

| Multi-Spec Compatibility | Supports various bag types and sizes | Flexible adaptation for different products and client requirements |

Technical Parameters (Example – Customizable)

| Parameter | Range |

| Packaging Speed | 15–40 bags/min (depending on product & bag type) |

| Packaging Weight | 10–2000g (customizable) |

| Bag Types | Pillow bag, Gusset bag, Block bottom bag |

| Packaging Material | PE/PP/laminated films, aluminum foil bags, others |

| Power Supply | 380V / 50Hz / 3-phase (customizable) |

| Footprint | 8–15 m² (depending on configuration) |

| Working Temperature | 0–45°C |

| Compressed Air | 0.6MPa |

Applicable Industries

- Food: Nuts, candies, chocolates, puffed snacks, dried fruits, coffee beans, seasonings

- Agriculture: Seeds, feed pellets

- Chemical: Granular chemical materials

- Daily Chemicals: Laundry powder, granular detergents

- Pharmaceutical: Granular medicines (GMP-compliant options available)

FAQ

Q1: What types of products can be packaged?

A1: Granules, pieces, powders, and small items such as nuts, candies, coffee beans, seeds, feed pellets, and laundry powder.

Q2: Is the production speed adjustable?

A2: Yes, the speed can be adjusted via the multihead weigher and VFFS machine to accommodate different output requirements.

Q3: Can the line handle multiple bag types?

A3: Yes, including pillow bags, gusset bags, block bottom bags, and self-standing zip-lock bags.

Q4: Can the equipment be purchased as individual machines or as a complete line?

A4: Both options are available depending on client needs, providing flexible configurations.

Q5: What are the key advantages of this production line?

A5: Continuous, high-speed, and fully automated operation ensures accurate weight, consistent packaging quality, reduced labor costs, higher throughput, and compatibility with multiple products and packaging formats.