A VFFS machine with multi-head weigher is one of the most popular and efficient solutions in the packaging industry today.

It combines high-speed automation with precise weighing, ideal for almost everything, snack food packaging, dry goods, frozen food, pet food, and more.

Let’s take a closer look at how this smart packaging system works—step by step.

What Is a VFFS with Multi-head Weigher?

The system combines two core technologies: a Vertical Form Fill Seal (VFFS) machine, and a multi-head weighing and filling machine.

The VFFS unit automatically forms, fills, and seals bags in a vertical direction from a roll of film.

The multi-head weigher accurately measures the product to be filled into each bag.

Why This Automatic Packaging Machine?

If you’re packing irregular or granular products, this setup is perfect. This automatic packaging machine ensures consistent pouch quality, minimal product loss, and reduced labor costs.

It is ideal for free-flowing products such as nuts, candies, coffee beans, chips, cereals, and small hardware.

Its precision and speed make it a preferred pouch packaging machine for mass production environments.

Step-by-Step Workflow of the VFFS + Multi-head Weigher System

Here’s how the system runs from product loading to finished bag.

1. Product Feeding

Products are first delivered into the multi-head weigher, typically by a Z-type conveyor.

The feeding system ensures a continuous and stable supply to prevent downtime.

Consistent feeding improves both speed and weighing accuracy.

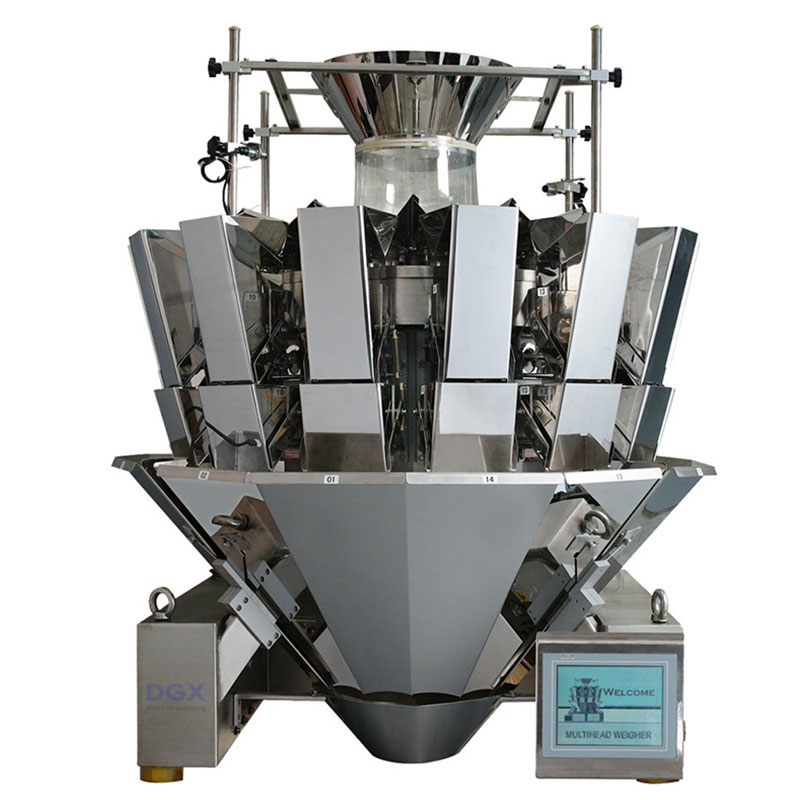

2. Weighing Process by the Multi-head Weigher

The multi-head weighing system includes several weigh hoppers, typically 10 to 14.

Each head weighs a portion of the product using load cells.

Then, the system instantly calculates the best combination that meets your target weight.

This ensures high-speed operation with minimal error.

3. Weighing Accuracy and Control

This system performs hundreds of calculations per second.

It chooses the most accurate combination with minimal deviation, reducing product giveaway.

Real-time weight monitoring helps maintain consistency across all packaged units.

4. Synchronization with the VFFS Machine

The weigher and the vertical form fill seal machine are fully synchronized.

As soon as the weigher finishes selecting the correct weight, it signals the VFFS machine to begin the bag filling sequence.

This ensures continuous, high-speed production without downtime.

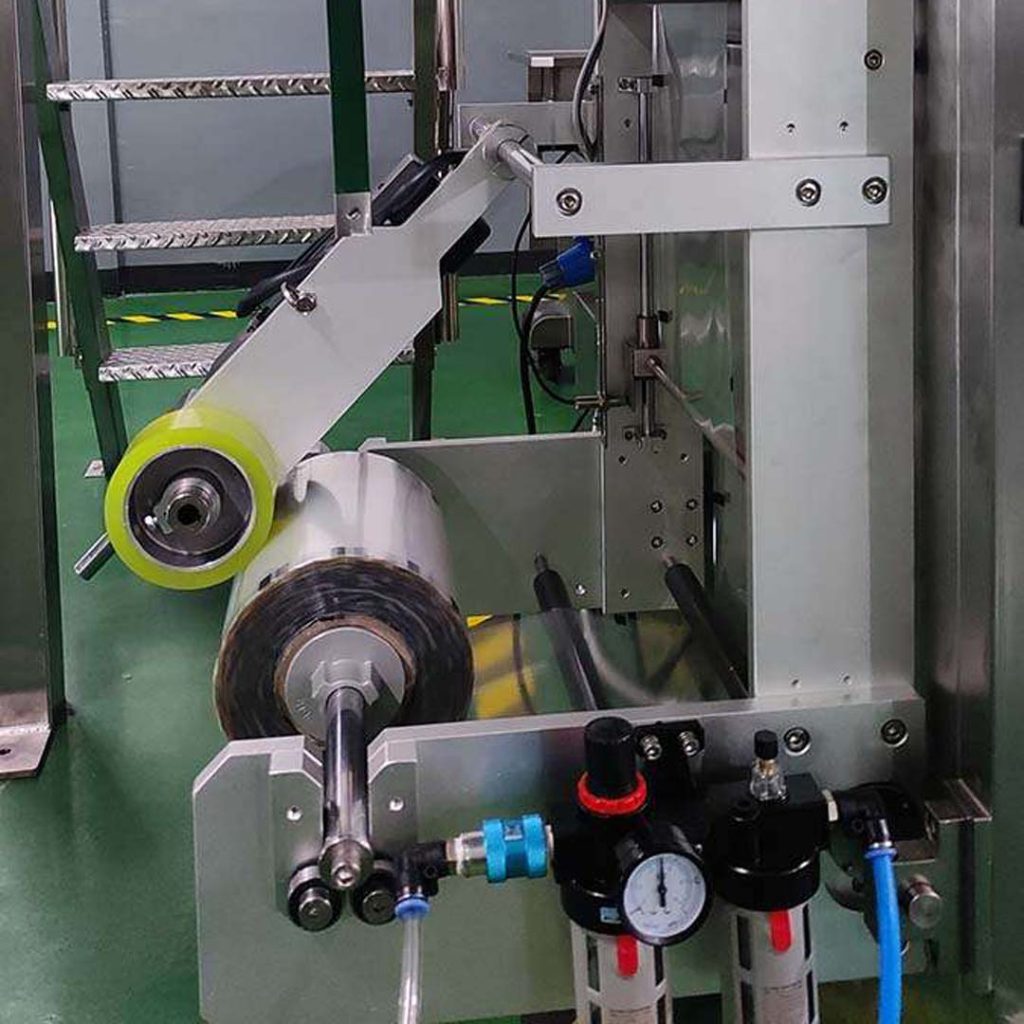

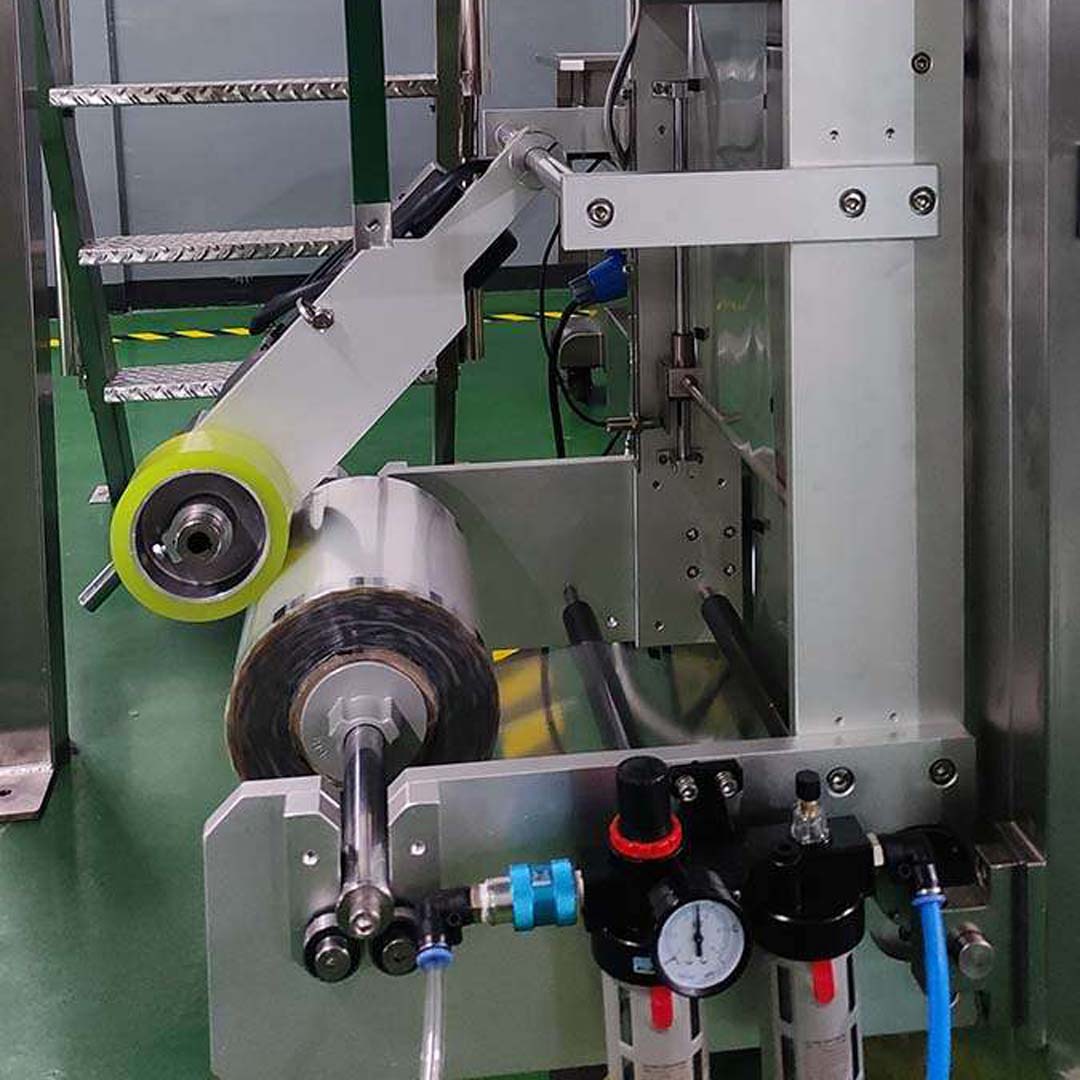

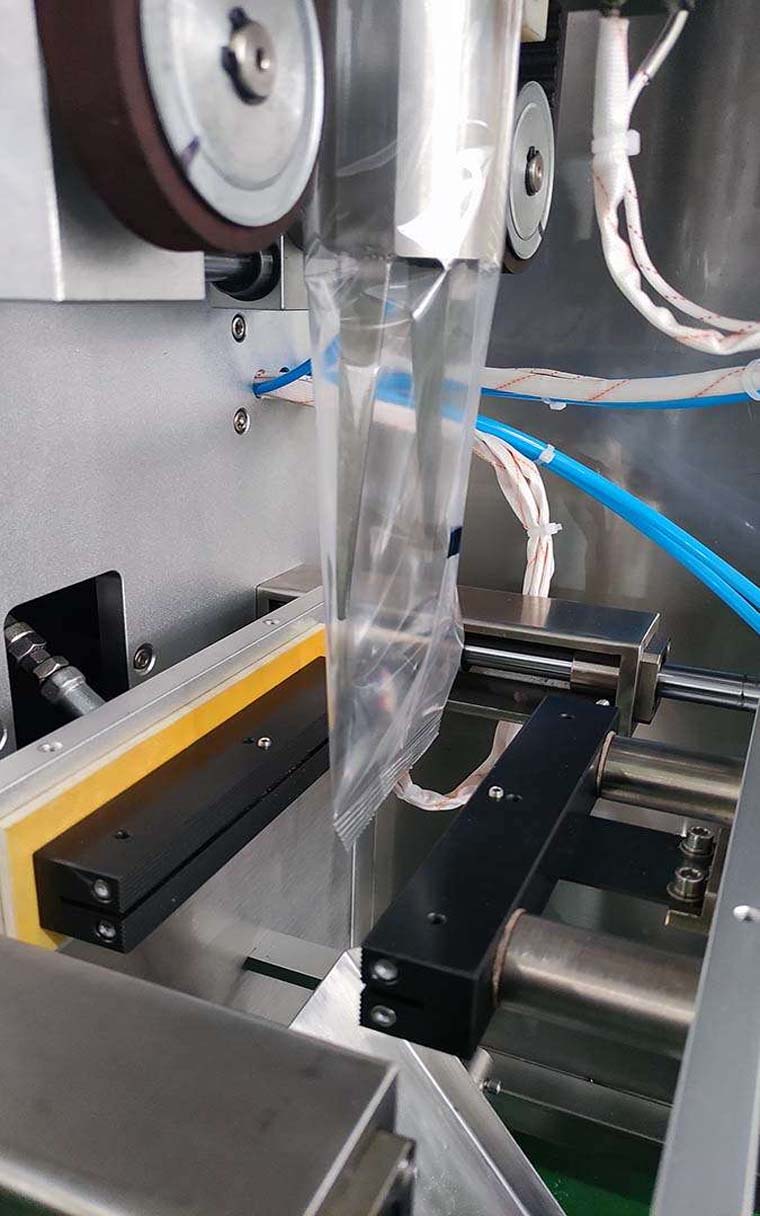

5. Film Unwinding and Bag Forming

The bag forming filling sealing system pulls packaging film from a roll and shapes it into a tube using a forming collar.

The vertical seal bar joins the edges to form the bag’s back seam.

The film is then pulled downward to the next station for product filling.

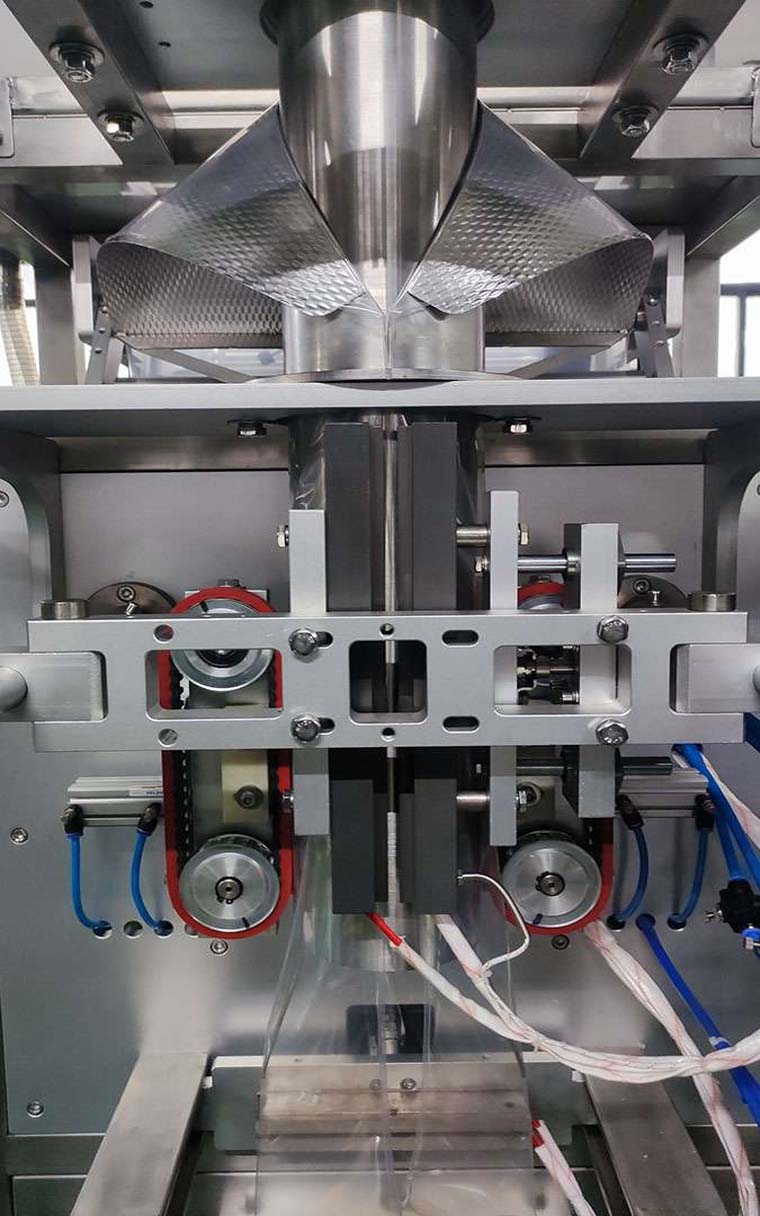

6. Filling and Horizontal Sealing

Once the bag’s bottom is sealed, the weighed product drops into the open tube through the center filling chute.

After filling, horizontal sealing jaws close to seal the top of the bag and cut it off.

This step completes the full bag, while preparing the next pouch below.

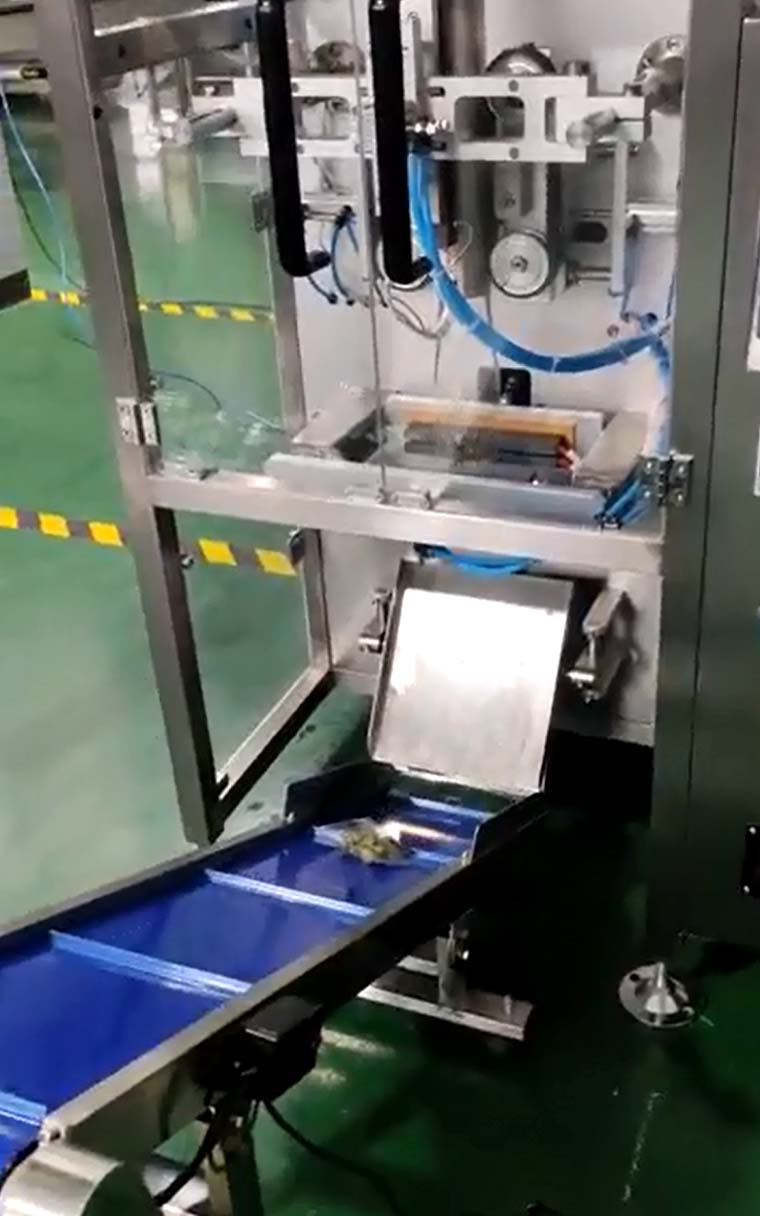

7. Finished Bag Discharge

The sealed pouch is dropped onto an exit conveyor for downstream operations.

Options include check-weighing, metal detection, labeling, or cartoning.

This ensures quality control and smooth integration with other packaging equipment.

Compatible Bag Types

The VFFS machine with multi-head weigher can produce:

Pillow pouches

Gusseted bags

Quad seal bags

Hanging hole bags

Resealable zipper bags (optional)

Custom printed packaging film support

Key Features and Advantages

High Accuracy: Minimal weight error, excellent product control

High Speed: Up to 80–100 bags per minute depending on product

Versatile Materials: Works with laminated film, PE, aluminum foil, and more

User-Friendly: Touchscreen HMI, multi-language interface, recipe memory

Flexible Design: Easily adjustable for different bag sizes and weights

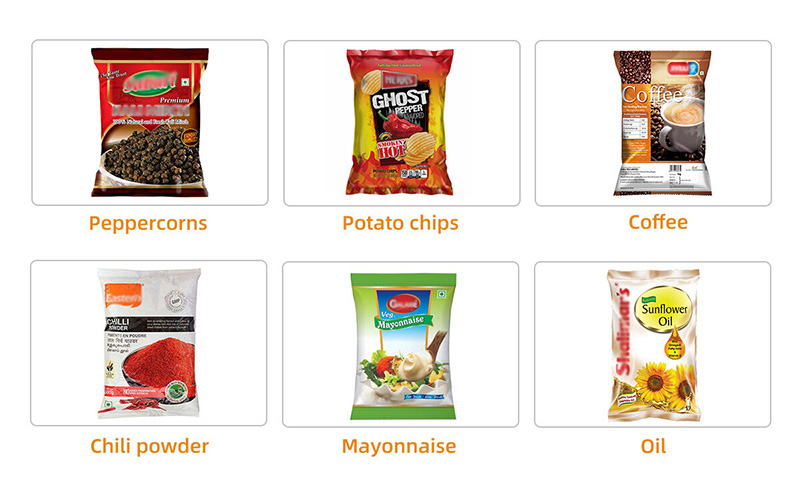

Applications of This Pouch Packaging Machine

Snack food packaging: Chips, popcorn, trail mix, peanuts

Frozen food packaging: Vegetables, dumplings, seafood

Hardware packaging: Screws, bolts, fasteners

Grain and powder packaging: Beans, rice, coffee, pet food

Optional Auxiliary Equipment

Enhance your automatic packaging line with:

Nitrogen flushing for extended shelf life

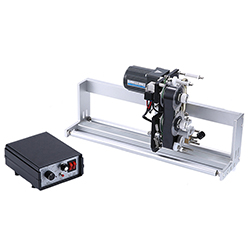

Printer for batch/date coding

Metal detector

Check weigher

Auto film centering and tension control

Rotary collecting table

Conclusion: A Smart Investment for Modern Packaging

A VFFS machine with multi-head weigher is a reliable and scalable solution for manufacturers aiming to improve efficiency and accuracy.

It combines precision weighing with fully automated bag forming and sealing, minimizing waste and maximizing output.

If you’re looking for a high-performance bag forming filling sealing system, this setup is a powerful choice.