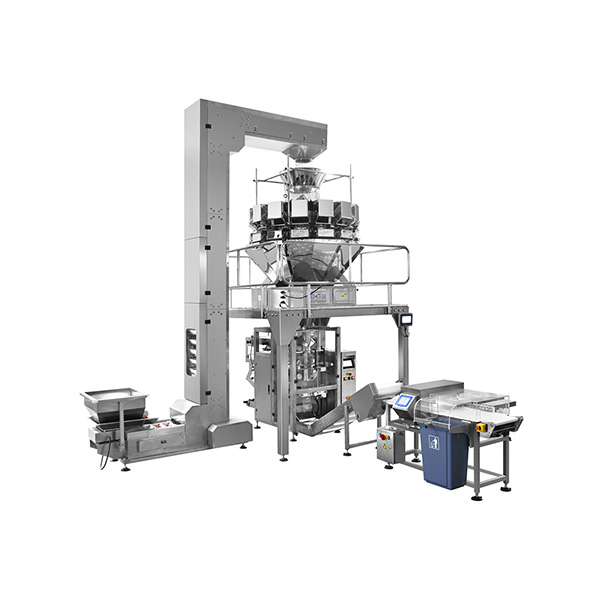

Best VFFS China Manufacturer

High-speed, precise, and durable VFFS packaging machines for various industries.

- High Efficiency & Speed – Advanced servo control ensures fast and stable operation.

- Versatile Applications – Suitable for granules, powders, liquids, and solid products.

- Precision Filling & Sealing – Guarantees airtight packaging with minimal waste.

- User-Friendly Interface – Intelligent touchscreen for easy operation and adjustments.

- Tailored Solutions – Custom machine configurations for specific product requirements.

- Technical Support & After-Sales Service – Comprehensive guidance for operation and global spare parts supply.

DGX VFFS Packaging Machine Series

DGX VFFS Packaging Machine Series offers an advanced and automated packaging solution for various industries, including food, beverages, cosmetics, and industrial products. These machines ensure high-speed, precise, and efficient packaging, adapting to different bag types and sizes. With intelligent PLC control systems, our VFFS machines provide consistent packaging quality, reducing material waste and enhancing production efficiency. User-friendly interfaces and easy maintenance features make operation simple while ensuring long-term reliability. Choosing DGX VFFS packaging machines helps businesses lower labor costs, improve product consistency, and enhance overall market competitiveness. Additionally, we provide comprehensive after-sales support to ensure stable machine operation.

DGX VFFS machines achieve 30-120 bags per minute with ±0.5% weight accuracy. Our advanced servo-driven film pulling system guarantees smooth and precise bag forming.

Built with 304/316 stainless steel, our machines comply with GMP and food safety standards, ensuring durability and easy cleaning. High-quality Teflon-coated sealing jaws provide reliable and airtight sealing for different packaging films.

DGX offers fully customized configurations to suit specific product and packaging requirements. We also provide branding support for customized bag printing and film designs.

We offer on-site installation, operator training, 24/7 technical assistance, and a full stock of spare parts to ensure smooth long-term operation.

Why Choose DGX VFFS Packaging Machines for Your Business?

DGX VFFS Packaging Machines offer a high-speed, automated solution designed for precision and efficiency. Our machines support various bag types and sizes, ensuring flexible packaging for industries like food, pharmaceuticals, and daily necessities. Choosing DGX means reducing labor costs, increasing output, and maintaining top-tier product quality.

Vertical Form Fill Seal Applications

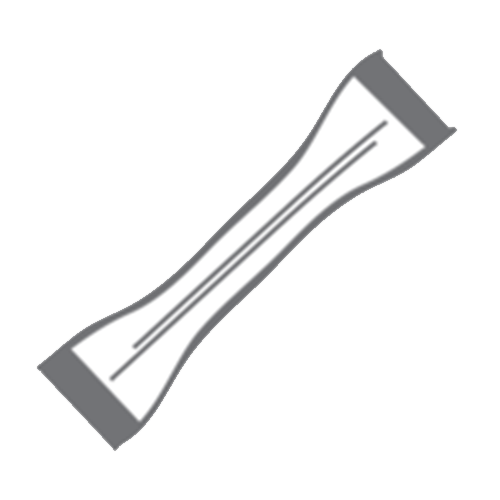

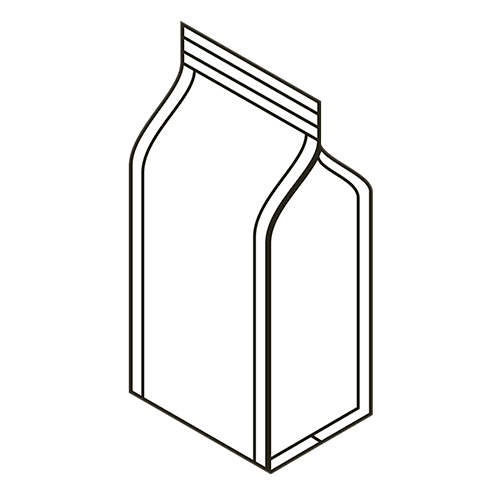

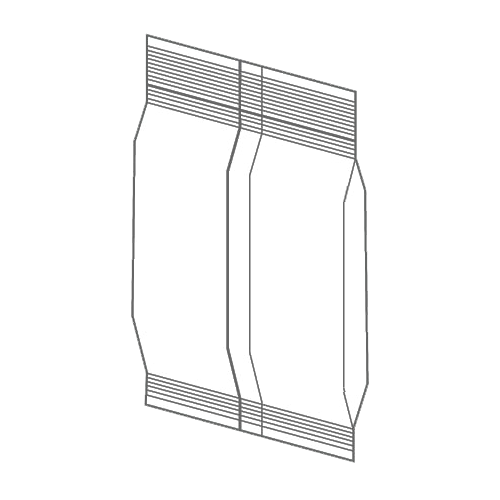

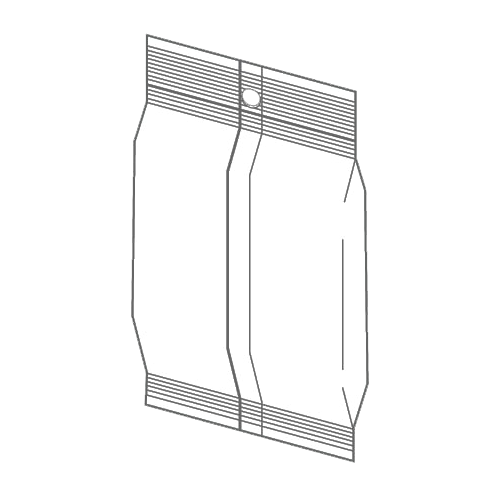

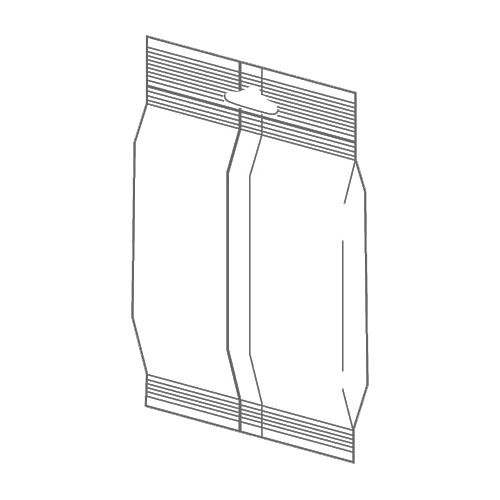

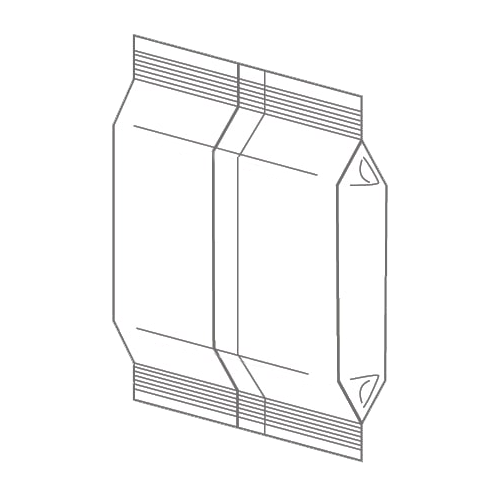

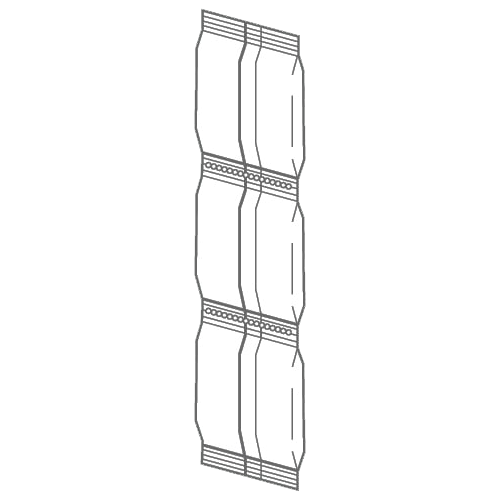

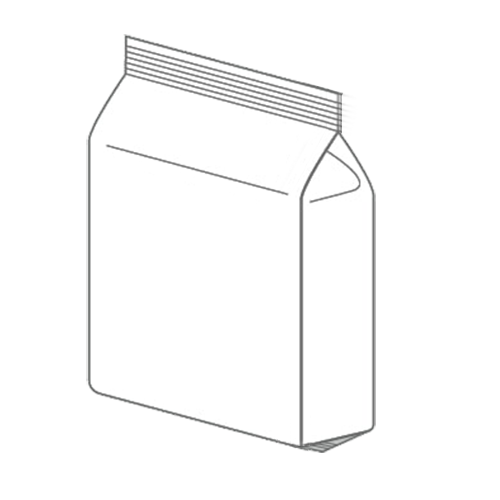

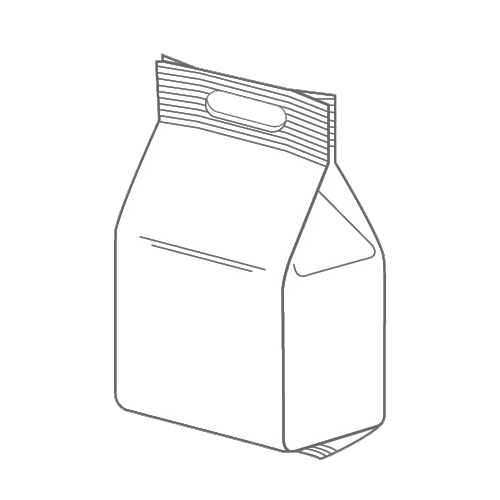

Bag Type

FAQs of Vertical Form Fill Seal

A VFFS (Vertical Form Fill Seal) machine is an automated packaging solution that forms, fills, and seals bags in a vertical process. It is widely used in food, pharmaceuticals, cosmetics, and industrial packaging.

VFFS machines can package a variety of products, including granules, powders, liquids, and solid items such as snacks, coffee, sugar, pet food, detergent, and more.

Our VFFS machines support pillow bag, gusseted bag, flat-bottom bag, 3-side and 4-side seal bag, and stick bag, among others.

DGX VFFS machines use precision weighing, auger fillers, volumetric cups, or liquid pumps to ensure accurate product filling and reduce material waste.

Yes, our VFFS machines support various packaging films, including laminated films, aluminum foil, PE, PP, and biodegradable materials to meet different industry needs.

Speed varies by model and product type, typically ranging from 30 to 120 bags per minute, ensuring high-efficiency production.

Yes, DGX VFFS machines has user-friendly touch screen interfaces, automatic troubleshooting, and quick-changeover designs for easy operation and maintenance.

Absolutely! We offer installation guidance, training, spare parts supply, and 24/7 after-sales support to ensure smooth machine operation.

Yes, we provide customized solutions based on your product, bag type and size, and production requirements to maximize efficiency and output.

Contact DGX today! Our experts will help you select the most suitable model based on your product type, production capacity, and packaging requirements.