DGX L-Bar Sealer | Automatic Shrink Wrapping & Packaging Machine

The DGX L-Bar Sealer is a high-efficiency automatic sealing and cutting machine designed for POF, PP, PVC, and PE shrink films. FL serices integrates core functions like automatic film feeding, precise sealing and cutting, and one-touch adjustment for various product sizes (e.g., boxes, electronics, consumer goods). It offers precise sealing, smooth operation, and high packaging speed, making it ideal for industrial packaging, book, food, cosmetic, or hardware product wrapping.

Featuring a high-precision temperature controller and durable alloy sealing blades, it ensures strong, seamless seals, boosting packaging efficiency by over 27%. This machine delivers consistent, professional results while improving production line efficiency. So it redues labor costs and driving operational excellence.

- Full Automation: Enables continuous operation with conveyor systems, significantly reducing labor costs.

- Precision Sealing: Adopts advanced temperature control and Teflon-coated sealing blade ensures perfect seals with various films like POF, PP, PVC, and PE.

- Robust Construction: Industrial-grade alloy blades and sturdy frame guarantee long-term reliability and minimal downtime.

- Quick-Change Flexibility: Easy adjustment for different product dimensions enhances packaging flexibility.

- Energy Efficient: Low-power consumption design supports sustainable and cost-effective operations.

DGX Automatic L-Bar Sealer Machine Description | Industrial Shrink Wrapping System

The DGX FL Series Automatic L-Bar Sealer is engineered to deliver efficient and reliable shrink packaging solutions for diverse industries. It automatically completes sealing and cutting in one step, ensuring neat, consistent, and strong seals with minimal operator intervention.

It is built around an intelligent control system that automatically triggers the sealing and cutting cycle via photoelectric sensors. Its unique L-shaped blade efficiently creates seals in one motion, eliminating misalignment common in manual packaging. Whether used for bottles, boxes, books, electronic parts, or food products, it ensures tight packaging that protects goods from dust and moisture while enhancing shelf appearance.

Capable of high-speed operation (up to 30 packages/minute) and featuring robust safety mechanisms, it drastically reduces maintenance needs and production stoppages. For factories, packaging workshops, and e-commerce fulfillment centers, this machine helps reduce labor costs, increase packaging speed, and improve production automation.

DGX provides customizable models to suit your specific product size and film requirements, ensuring optimal efficiency and stability for every application.

FL Series Automatic L-Bar Sealer Technical Specification

| Model | FL-450 | FL-550 | FL-750 |

| Packing Size(Max.) | L+Hx1.5≤500mm W+Hx1.5≤400mm H≤150mm | L+Hx1.5≤600mm W+Hx1.5≤500mm H≤150mm | L+Hx1.5≤800mm W+Hx1.5≤700mm H≤200mm |

| Capacity | 15-30 Packages/min(depands on products) | ||

| Power Supply | AC220V(1p) 50/60Hz(Special Voltages Available Upon Request) | ||

| Air Supply | 0.6-0.8MPa | ||

| Shrink Film | POF/PE (For specific films or anti-static varieties, please consult with our technical team) | ||

| Power | 1.5kW | 2.2Kw | 3kW |

| Dimension | 1650x880x1450mm | 1950x1000x1450mm | 2250x1200x1550mm |

| Weight | 280kg | 350kg | 550kg |

Request Your Custom Packaging Solution Today!

Contact DGX for professional L-Bar Sealer solutions to boost your packaging efficiency and quality.

Industries & Applications

The FL Series Fully Automatic L-Sealer is your dependable assistant for enhancing product presentation and achieving streamlined, high-volume packaging. It is the ideal solution for products that demand efficiency, a neat appearance, and reliable protection against dust and moisture.

Product Video

DGX L-Bar Sealer | Automatic Shrink Wrapping & Packaging Machine Detail Display

Intuitive and user-friendly. Configure all parameters with just a few taps.

The sealing area is guarded by an acrylic cover and an automatic alarm for complete peace of mind.

Equipped with a photoelectric sensor at the material entrance, guaranteeing accurate item detection for seamless operation.

Our sealing blade intelligently retracts when it encounters an object, preventing damage to both your products and the machine.

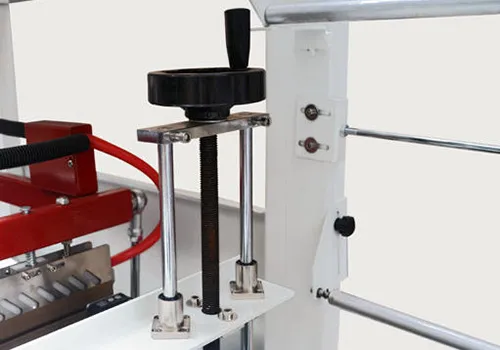

Quickly set the guide plate height to perfectly match your product’s size.

Built for heavy loads and fast acceleration.

An L-Bar Sealer is an automated machine that forms an “L”-shaped seal around a product. The DGX sealer uses a film roll and an L-shaped sealing bar. The product moves into the machine on a conveyor, the film is draped over it, and the hot bar descends to seal and cut the film simultaneously, creating a tight, professional package.

The DGX L-Bar Sealer is highly versatile. It is ideal for:

Industries: Food & Beverage, Pharmaceuticals, Cosmetics, Electronics, Stationery, and Consumer Goods.

Products: Boxes, books, CDs/DVDs, multi-packs (bundling), bottles, and any uniformly shaped items that require a secure, shrink-wrapped package.

It is compatible with most common shrink films, including Polyolefin(POF), Polypropylene(PP), Polyvinyl chloride(PVC), Polyethylene(PE). For specific films or anti-static varieties, please consult with our technical team for potential machine configuration adjustments.

The machine can achieve speeds of up to 30 packages per minute. The actual throughput depends on product size and operator speed, but it is designed for medium to high-volume production lines.

Not at all. The DGX L-Bar Sealer is designed for quick changeover. Key parameters like sealing time and temperature can be easily adjusted via the user-friendly digital control panel. The sealing height can often be mechanically adjusted to accommodate different product heights.

Manual: Requires manual product and film placement.

Semi-Automatic: Operator places the product; sealing and cutting are automatic.

Automatic: Fully automated feeding, sealing, and discharge—ideal for high-volume production lines.

Yes. It’s designed to work seamlessly with DGX shrink tunnels (RS series) for full packaging automation — from sealing to heat shrinking.

Our key advantages include:

- Robust Construction: Industrial-grade components for long-term durability.

- Precision Control: Advanced digital temperature control for perfect seals every time.

- Ease of Use: Simple setup and intuitive operation reduce training time.

- Excellent Support: Comprehensive global technical support and readily available spare parts.

Absolutely. DGX provides customized sealing dimensions, film widths, and power configurations based on your product size and factory layout. OEM and ODM services are available.

Yes. We offer several optional features, such as custom jigs/fixtures for irregularly shaped products, anti-static modules for sensitive electronics, and extended conveyor lengths for integration into fully automated lines. Contact us to discuss your specific requirements.

DGX offers a standard one-year warranty on parts and manufacturing defects. We provide detailed documentation, online support, and a global network of service technicians. Extended warranty and on-site training options are also available.

You can request a quote or schedule a live demo (online or in-person) by contacting us directly through our Contact Us page or by emailing [email protected]. Please provide your primary product dimensions and expected output for a faster, more accurate response.

Core Strengths of FL Series L-Shaped Sealing and Cutting Machine

Intelligent & Labor-Saving: Reduce Costs, Boost Efficiency

- Strengths: The integrated automated control system enables one-touch start/stop, automatic feeding, sealing/cutting, and collection. Its simple operation requires minimal operator skill.

- Customer Benefits: Greatly reduces dependence on skilled workers, directly lowering labor and management costs. The automated process also prevents human error, ensuring consistent improvements in both packaging efficiency and quality.

High Efficiency & Versatility: One Machine for Multiple Uses

- Strengths: Features an advanced L-shaped sealing and cutting blade design that seamlessly adapts to various product sizes. Supports quick film changes, allowing one machine to handle most packaging tasks.

- Customer Benefits: Eliminates the need to purchase multiple machines for different product sizes, significantly reducing procurement costs and equipment footprint. Rapid switching greatly enhances production line responsiveness and flexibility.

Precision Sealing & Cutting: Superior Quality Assurance

- Strengths: Equipped with a high-precision photoelectric tracking system and constant temperature control technology. Ensures straight sealing lines, strong seals, and smooth, burr-free cuts—eliminating common issues such as wire drawing or charring found in traditional systems.

- Customer Benefits: Delivers a flawless, uniform packaging appearance that enhances product presentation and brand image. The durable seal effectively prevents dust and moisture ingress during transportation, protecting product integrity.

Robust & Durable: Unwavering Reliability

- Strengths: The core structure is constructed from high-strength alloy materials and precision-machined components. Key parts undergo special reinforcement treatment to prevent deformation or wear during prolonged high-intensity operation.

- Customer Benefits: Minimizes equipment failure rates and maintenance needs, ensuring uninterrupted production. Effectively reduces downtime-related losses, extends equipment lifespan, and maximizes return on investment.

More Information

With 10+ years of experience in packaging machinery manufacturing, DGX provides CE-certified sealing and shrinking systems with global technical support, OEM customization, and fast delivery.

For advanced applications, the DGX L-Bar Sealer offers modular components, including anti-static film treatment and custom jigs for delicate items. The machine is backed by a lifetime technical support to ensure uninterrupted operation for our partners.

For detailed specifications, industry case studies, or to arrange a live demo, please visit our product page or contact our sales team directly.