BF-S Dual Side Sealer

The DGX BF-S Series Dual Side Sealer is a fully automatic machine for side sealing and shrink wrapping, designed for high-speed packaging of long or irregular products. Featuring a continuous side sealing system and an automatic feeding device, it delivers efficient, stable, and precise sealing performance. Its main advantages include significantly increasing packaging throughput, greatly reducing labor costs and material waste, and providing a neat, secure seal. It is ideal for industrial packaging lines and large-scale production.

Continuous Side Sealing System – Ensures smooth and firm sealing for products of unlimited length.

High-Speed & Stable Performance – Adopts advanced servo motor control, ensuring fast packaging with minimal downtime.

Flexible Product Compatibility – Capable of handling various product sizes without frequent mold changes.

Energy-Saving Shrink Tunnel Integration – Paired with DGX shrink tunnel for low energy consumption and perfect finish.

User-Friendly Operation – Touch screen control, easy adjustment, and simple maintenance for operators.

Robust Construction, Low Maintenance – Built with industrial-grade high-strength materials and branded core components, ensuring long-term, stable operation.

Dual Side Sealer Automatic Shrink Wrapping Machine – Continuous Side Sealing for Long Products

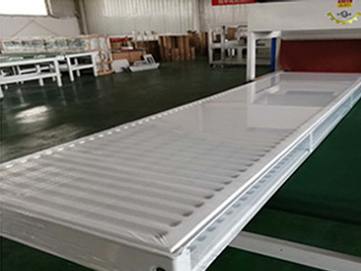

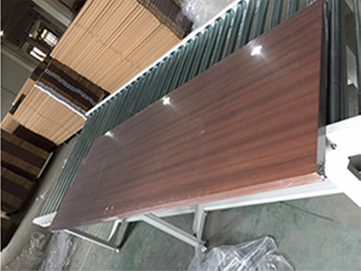

The DGX Dual Side Sealer is designed for packaging long items like doors, panels, profiles, and cartons. With continuous side sealing technology, it removes length restrictions and guarantees consistent packaging results. Built-in automatic feeding, film tracking, and temperature control systems provide outstanding reliability and efficiency. Its compact design saves valuable floor space while preserving high throughput.

For manufacturers aiming for high output and low maintenance costs, the DGX Dual Side Sealer provides an ideal solution — combining speed, precision, and energy savings in a single compact machine.

Investing in our Dual Side Sealer boosts your business’s efficiency. You will directly notice:

– Major reduction in operational costs: cuts dependence on skilled labor (one operator can monitor several lines) and minimizes material waste with precise tape application.

– Significant increase in productivity and output: the fast, continuous sealing process removes manual bottlenecks, enabling your line to run at its maximum intended speed and speeding up order fulfillment.

– Consistent packaging quality and improved brand image: ensures every product is neatly and securely sealed, lowering the risk of transit damage and enhancing the customer experience and brand professionalism.

– High return on investment (ROI): typically recovered quickly—within 12-18 months—due to savings in labor and materials, making it a wise long-term investment.

BF-S Series Dual Side Sealer Technical Specification

| Model | BF-13030S |

| Packing Size(Max.) | 60mm≤(W+H)≤1250mm, H≤300mm |

| Shrimk Film | PE |

| Thickness of Film | 0.04-0.18mm |

| Horizontal Blade Size | 1300mm |

| Workbench Height | 825±25mm |

| Capacity | 0-15m/min (depends on products) |

| Power Supply | AC220V(1p) 50/60Hz (Special Voltages Available Upon Request) |

| Air Supply | 0.6-0.8MPa |

| Power | 6kW |

| Dimension | 2380x1800x1780mm |

| Weight | 1500kg |

Get a Customized Dual Side Sealer Solution Today

Contact DGX Machinery for tailored configurations and competitive pricing!

Industries & Applications

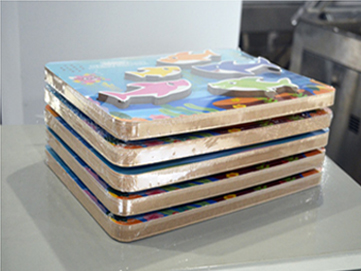

The BF-S series fully automatic double-sided sealing packaging machine is widely used across various industries due to its unique double-sided sealing technology and exceptional packaging capabilities for large and heavy items, including flooring, door panels, furniture (such as ladders and mattresses), tiles, and boards. The packaging length is unlimited, providing full sealing protection against dust, moisture, and scratches.

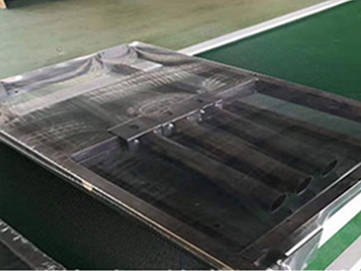

Detail Display

Color touchscreen with one-touch presets and role-based access control.

±0.5mm detection accuracy for precise sealing alignment across products.

Automatically retracts upon non-film contact to prevent damage and ensure safety.

Premium coated blades for lasting performance and superior durability.

Precision dial for fine height adjustment to fit various product sizes.

Teflon® coated for non-stick performance and strong, seamless seals.

Our Dual Side Sealer can reach a maximum packaging speed of up to 35 packs per minute, making it ideal for high-demand production lines and ensuring efficient packaging even in large-scale operations.

The Dual Side Sealer is compatible with a variety of shrink films, including PE, POF, and PVC films. However, we strongly recommend using PE film (Polyethylene film) for the best results, especially for products that require cost-effective, flexible, and secure packaging.

Great Shrinkability: PE film provides excellent shrinkage, conforming tightly around products, ensuring a secure and neat seal. This is particularly important for irregularly shaped or long products, which the Dual Side Sealer handles perfectly.

Cost-Effective: Compared to other shrink films, PE is generally more affordable, making it a cost-efficient choice for high-volume packaging.

Durability & Flexibility: PE film is highly resistant to tears and punctures, making it ideal for protecting products during handling and transportation.

Food-Safe & Non-Toxic: PE film meets industry standards for food packaging, ensuring that it is safe for direct contact with edible products.

Eco-Friendly: As a recyclable material, PE film is a more environmentally friendly option compared to PVC and other non-recyclable films.

By using PE film with the Dual Side Sealer, you benefit from reliable, efficient, and cost-effective packaging that is both secure and environmentally conscious.

Not at all. It comes equipped with an intuitive touch screen control system, making it easy to operate. The user interface is simple, reducing the complexity of training and day-to-day operation.

Yes, the 2-Side Sealer offers great flexibility and can handle products of various sizes and shapes. No need to frequently change molds, allowing quick adjustments to accommodate different packaging requirements.

Yes, the Sealer features an energy-efficient shrink tunnel and an intelligent temperature control system. It automatically adjusts the shrink temperature, reducing energy consumption while maintaining optimal packaging performance.

The machine is designed for easy maintenance, with components that are simple to clean and an easy troubleshooting process. Regularly checking the sealing parts and lubrication system will ensure long-term, efficient operation.

If the machine encounters any issues, you can contact our after-sales support team. We provide remote diagnostics and necessary repair services. Additionally, we offer regular inspections and maintenance services during the warranty period.

The typical delivery time is 4-6 weeks. The exact delivery time may vary depending on the order quantity and customization requirements.

The More

- Applicable Films: PE shrink film

- Sealing Type: Continuous side sealing + cross sealing

- Packaging Speed: Up to 15 m/min

- Product Length: Unlimited (continuous side sealing design)

- Power Supply: AC220V, 50/60Hz (Special Voltages Available Upon Request)

- Control System: Core PLC and touchscreen HMI for easy parameter setting and fault self-diagnosis.

- Frame Material: High-quality carbon steel / stainless steel for durability in various industrial environments.

- Optional Devices: Automatic feeder, shrink tunnel, labeling or printing system

- After-Sales Service & Support:

-We provide comprehensive installation, commissioning, and operator training.

-A rapid spare parts supply chain and a professional technical support team ensure your equipment’s continuous high-performance operation.