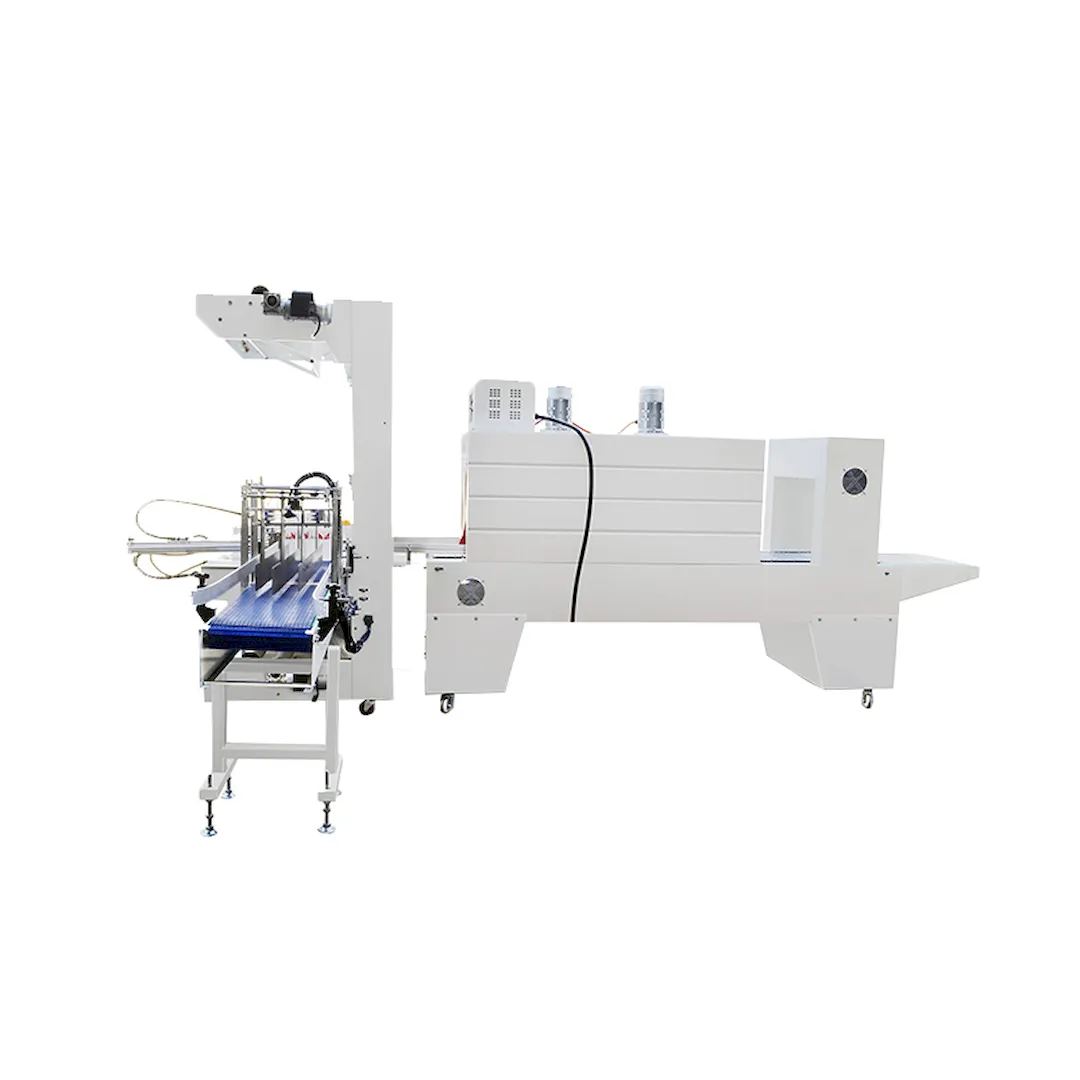

XT-C Series Side-Push PE Film Sleeve Wrapping Machine

The XT-C Series Side-Push PE Film Sleeve Wrapping Machine is engineered for high-volume industrial secondary packaging, offering automated side-push feeding, PE film sleeve wrapping, and shrink bundling for medium-to-large, multi-pack, heavy-load, and irregular products. Designed for manufacturers, packaging suppliers, beverage producers, printing facilities, and distribution centers, it ensures stable bundling strength, reduced labor intensity, and consistently high operational throughput.

Stable side-push feeding for long, irregular, and heavy multipacks.

High-efficiency sealing & uniform shrink ensure tight, durable packaging.

30–60% cost reduction by replacing traditional carton packaging with PE film.

Fast changeover system supports multi-SKU production with minimal downtime.

Automation-ready architecture connects seamlessly with palletizing and MES systems.

XT-C Series Side-Push PE Film Sleeve Wrapping Machine Description

The XT-C Series Side-Push PE Film Sleeve Wrapping Machine is engineered as an advanced secondary packaging solution catering to industrial-grade production environments that demand high-speed, heavy-load, and multi-size product bundling. Designed with a robust side-push feeding mechanism, this model demonstrates exceptional stability when handling elongated items, stacked units, shrink-ready multipacks, and irregularly shaped products that conventional top-feeding systems cannot efficiently process.

Built for manufacturing enterprises, packaging contractors, OEM plants, FMCG producers, hardware suppliers, and distribution warehouses, the XT-C Series ensures operational reliability across extended production shifts. Its PE film sleeve structure provides secure bundling strength with strong puncture resistance, enabling product units to maintain integrity during warehousing, palletizing, and long-distance transportation.

Across multiple industries, the XT-C Series generates substantial operational value:

In beverage production, it boosts the efficiency of bottle and can multipacking while maintaining tight bundle stability.

In printing and publishing, it supports high-speed stacking and clean shrink-wrapping of books, magazines, and catalogs without deformation.

In hardware and building materials, it provides secure bundling for long profiles, pipes, tools, and heavy components.

In household product manufacturing, it enables economical multi-unit retail and wholesale packaging.

In logistics and distribution centers, it ensures dust-proof, anti-scatter, high-integrity bundling for mixed SKUs and transport units.

The XT-C Series ultimately offers a scalable, automation-ready solution that reduces labor, increases packaging throughput, strengthens product protection, and maximizes cost efficiency—making it an ideal asset for modern industrial packaging systems.

XT-Z Series Fully Automatic In-line Sleeve Wrapping Machine Technical Specification

| Model | XT-6040C | RSE-6040A |

| Conveyor Speed | 15m/min(depands on products) | |

| Conveyor Loading | <30kg (Special weight customizable) | |

| Shrink Film | PE,POF, PVC,PP | |

| Film Thickness | 0.03-0.25mm | |

| Pack Size(Max.) | L600xW400xH350mm | W500xH350mm |

| Pack Size(Min.) | L250xW50xH100mm | |

| Tunnel Size | 1800x600x400mm | |

| Power Supply | AC220V(1p) | AC380V(3p) |

| Air Supply | 0.4-0.6MPa | |

| Power | 1.5kW | 24kW |

| Dimension | 1060x1600x1930mm | 2800x950x1750mm |

| Weight | 380kg | 450kg |

Get XT-C Side-Push PE Film Sleeve Wrapping Packaging Solutions

Submit your quick inquiry now

XT-C Series Side-Push PE Film Sleeve Wrapping Machine Applications

- Beverage multipacks: bottled water, soda, beer, canned drinks

- Printing & publishing bundles: books, magazines, catalogs, brochures

- Household and daily chemical packaging: detergent bottles, tissue packs, cleaning products

- Hardware tools & building materials: tool kits, profiles, pipes, long-shaped goods

- Food industry bundles: boxed snacks, can packs, tray foods

- Electronics & appliance accessories: small appliances, long components

- Plastic product grouping: bottles, trays, buckets

- Logistics & distribution secondary transport packaging

The XT-C Series Side-Push PE Film Sleeve Wrapping Machine can handle round bottles, square bottles, cans, and irregular-shaped products. It is suitable for beverages, food, consumer goods, pharmaceuticals, and industrial products, with a modular design allowing quick product size changes.

The XT-C Series can reach up to 10 packages per minute. Speed may vary slightly depending on product size, film type, and production conditions. High-speed side-push technology ensures stable packaging even at maximum speed.

Yes, it supports PE, OPP, PVC, and other film types with varying thicknesses, meeting diverse requirements for durability and visual quality.

Absolutely. The machine is designed for high-capacity, high-efficiency production lines, reducing manual intervention and ensuring continuous operation, ideal for beverage factories, food plants, pharmaceutical packaging, and other industrial applications.

The XT-C Series features a user-friendly touch interface and an automatic alarm system, allowing non-specialized operators to quickly get started. Detailed manuals and training support are provided to help clients start production efficiently.

Built with industrial-grade materials and a modular design, the machine is easy to disassemble and clean. Regular maintenance is minimal, reducing costs while ensuring long-term stable operation.

Yes, the XT-C Series can connect with conveyors, labeling machines, shrink packaging machines, and other upstream/downstream equipment to create a fully automated production system, enhancing overall efficiency.

The precise side-push control system and smart alignment ensure each product sleeve is accurately positioned, minimizing waste and standardizing packaging appearance.

With high automation efficiency and labor cost reduction, the XT-C Series typically achieves ROI within 6-18 months, depending on production volume and application.

Yes, we provide tailored film sizes, packaging dimensions, and automation integration solutions to meet the specific needs of client production lines.

Comparison with Traditional Packaging

Compared with manual bundling or conventional carton packaging, the XT-C Series Side-Push PE Film Sleeve Wrapping Machine significantly enhances production line performance in cost efficiency, output capacity, packaging stability, and SKU adaptability. This solution is highly suitable for large-scale manufacturers, OEM factories, and automated packaging lines that require stable combination packaging and multi-SKU flexibility.

Comparison Table:

| Category | XT-C Side-Push PE Film Wrapping | Manual Bundling / Carton Packaging |

| Packaging Cost | PE film reduces cost by 30-60% | Higher cost due to cartons & tapes |

| Efficiency | 20-40 packs/min, significantly higher | 3-8 packs/min, labor dependent |

| Stability | Tight shrink, anti-shock, anti-loose | Easily deformed or broken |

| SKU Adaptability | Multiple sizes on one line | Requires frequent carton changes |

| Labor Requirement | One operator for the full line | Multiple labor positions |

| Product Display | Transparent film enhances visibility | Cartons cover the product |

The XT-C Series minimizes material costs, improves packaging quality consistency, and significantly enhances load stability for logistics, delivering measurable operational value for your business.

Pain Points – Solution Matrix

The XT-C Series offers targeted automation solutions designed to address key operational challenges across different manufacturing sectors. It enhances packaging stability, increases production throughput, and optimizes cost structure throughout the supply chain.

| Customer Pain Point | XT-C Solution | Business Value |

| Low packaging efficiency & high labor cost | Fully automated side-push feeding + sealing + shrinking line | 2-4× productivity increase, labor reduction |

| Frequent SKU changes | Adjustable film rack, guide rails, and pusher system | Faster changeover, 30-50% downtime reduction |

| Poor packaging consistency | Intelligent constant-temperature sealing + uniform shrink heating | Lower loose-pack rate, better load stability |

| High logistics damage rate | Tight shrink wrap with impact resistance | Fewer damage claims, improved delivery quality |

| Need for automation upgrade | Supports auto-collation, MES connectivity, and palletizing systems | Seamless transition to smart manufacturing |

The XT-C Series not only enhances packaging performance but also drives measurable operational improvements that translate into long-term cost savings and stronger competitive differentiation.