Smart Automatic L-Bar Sealer with PLC Control

The L-Bar Sealer with PLC Control is a fully automatic shrink packaging machine designed for high-precision film sealing and cutting. Featuring an advantage PLC system, it offers reliable, consistent sealing performance with minimal operator intervention. Perfect for mass production packaging lines, it supports a variety of shrink films (PE, POF, PVC) and ensures neat, tight, and attractive packaging results.

Intelligent PLC Control System: Simplifies operation and minimizes human error, ensuring consistent sealing results.

Precise Temperature & Cutting System: Feature: Independent temperature controllers and cutting knives guarantee neat sealing edges.

High-Speed Operation: Boosts productivity and supports continuous packaging in large-scale production.

Compatible with Various Shrink Films: Enhances flexibility for different product types and packaging requirements.

Compact Design with Safety Protection: Ensures operator safety while optimizing workshop space utilization.

L-Bar Sealer with PLC Control – Product Description

The L-Bar Sealer with PLC Control supplied by DGX Machinery, a leading packaging machine manufacturer and exporter, is an advanced shrink wrapping equipment designed for efficient and precise film sealing. This model combines intelligent PLC programming, adjustable sealing dimensions, and automatic temperature regulation to ensure consistent sealing quality and stable production output. As a professional L-Bar Sealer supplier, our machine is engineered for PE, POF, and PVC films, supporting diverse industrial packaging lines in food, cosmetics, electronics, and daily necessities sectors.

Featuring a compact structure and high-speed operation, the L-Bar Sealer offers smooth film feeding, automatic film trimming, and waste collection. Its durable alloy sealing blade provides clean and firm sealing without residue, while the integrated conveyor system allows seamless connection with heat shrink tunnels for fully automated packaging lines. The adjustable sealing area—typically 400×500mm or 500×600mm—makes it suitable for various product sizes and packaging forms, delivering professional and appealing results.

This automatic sealing machine is widely adopted by factories, distributors, and packaging solution providers seeking to upgrade their production automation. Reducing manual labor and improving packaging uniformity helps clients increase throughput and minimize operational costs. DGX Machinery provides reliable L-Bar Sealer for sale in both standard and customized specifications, ensuring our global partners receive stable performance, low maintenance, and exceptional value from every unit.

To help customers achieve higher efficiency and packaging consistency, the L-Bar Sealer with PLC Control is engineered with several advanced functions and user-oriented advantages, as highlighted below.

1. Smart & Stable Operation

Equipped with a PLC control panel, the L-Bar Sealer offers intuitive settings, auto diagnostics, and parameter memory, ensuring continuous and stable performance during high-speed packaging.

2. Clean & Consistent Sealing

Advanced sealing blades provide smooth and firm sealing lines without film sticking or burning. Customers benefit from improved product presentation and reduced packaging waste.

3. Energy Efficiency & Cost Savings

Optimized heater design reduces power consumption by up to 20%, lowering energy costs while maintaining high sealing accuracy.

4. Seamless Integration with Shrink Tunnels

Compatible with heat shrink tunnels, forming a fully automatic packaging line that increases throughput and minimizes operator involvement.

5. Built for Durability

Heavy-duty frame structure and high-quality components ensure long-term stability, minimal maintenance, and reduced downtime.

PLC L-Bar Sealer Technical Data

| Model | FL-450P | FL-550P | FL-750P |

| Packing Size(Max.) | L+Hx1.5≤500mm W+Hx1.5≤400mm H≤150mm |

L+Hx1.5≤500mm W+Hx1.5≤400mm H≤150mm |

L+Hx1.5≤500mm W+Hx1.5≤400mm H≤150mm |

| Capacity | 15-30 Packages/min(depands on products) | ||

| Power Supply | AC220V(1p) 50/60Hz(Special Voltages Available Upon Request) | ||

| Air Supply | 0.6-0.8MPa | ||

| Shrink Film | POF/PE (For specific films or anti-static varieties, please consult with our technical team) | ||

| Power | 1.5kW | 2.2kW | 3kW |

| Dimension | 1650x880x1450mm | 1950x1000x1450mm | 2250x1200x1550mm |

| Weight | 280kg | 350kg | 550kg |

Get the Best L-Bar Sealing Solution for Your Packaging Line!

Contact us now for price and customization details.

L-Bar Sealer with PLC Applications

Suitable for packaging food, cosmetics, stationery, hardware, pharmaceuticals, daily necessities, and electronic products, providing efficient sealing and shrink wrapping for retail and industrial packaging lines.

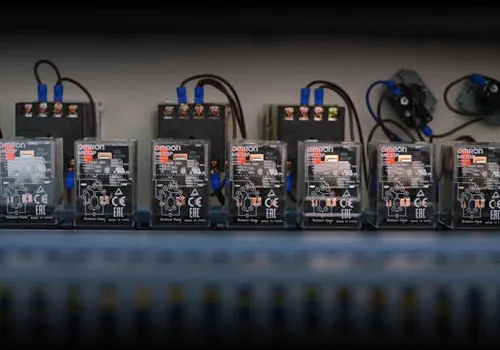

FL-P Series Smart PLC L-Bar Sealer Detail Display

Premium coated imported blades deliver exceptional durability and ensure long-lasting, high-performance cutting.

An integrated safety mechanism automatically retracts the sealing blade upon contact with non-film surfaces, preventing incorrect cutting and product damage.

Equipped with dedicated film-feed and sealing/cutting switches for simplified debugging, plus an emergency stop button for immediate shutdown.

Utilizing Omron relay components to guarantee stable performance and enhance overall operational reliability.

Accurately senses packaging position to provide precise operational control and ensure consistent processing.

Features intelligent PLC control with a visual operation interface for effortless and efficient human-machine interaction.

It supports PE, POF, and PVC shrink films.

No, thanks to the PLC system, most settings are automatic with minimal manual input.

Yes, it can be integrated with shrink tunnels, conveyors, and labeling systems.

Depending on the model, it can reach up to 25–35 packs per minute.

Minimal — only regular cleaning and periodic blade inspection are recommended.

L-Bar Sealer Features

| Feature | Description | Customer Benefit |

| PLC Intelligent Control | Advanced PLC system with touch screen, parameter memory, and auto diagnostics | Simplifies operation, reduces errors, and ensures consistent sealing quality |

| Adjustable Sealing Area | Standard 400×500mm / 500×600mm, customizable | Fits different product sizes, flexible for various packaging needs |

| High-Speed Operation | Stepper or servo motor driven film feeding and sealing | Increases throughput, ideal for industrial production lines |

| Compatible Films | PE, POF, PVC shrink films | Supports multiple packaging types, improves versatility |

| Safety Protection | Emergency stop, transparent guard cover | Ensures operator safety while monitoring the operation |

L-Bar Sealer Applications / Used For

| Application Area | Description |

| Food Packaging | Snacks, confectionery, bakery products – ensures hygienic, tight packaging |

| Cosmetics | Bottles, tubes, gift sets – professional sealing with attractive appearance |

| Electronics | Small electronics, accessories – protective shrink wrapping to prevent damage |

| Daily Necessities | Household products, stationery – improves shelf presentation and transport safety |

L-Bar Sealer Materials / Components

| Component | Material / Description |

| Machine Frame | Powder-coated steel for durability and corrosion resistance |

| Sealing Blade | Alloy steel with anti-stick coating, long-lasting |

| Conveyor Belt | Rubber or stainless steel, depending on the application |

| Control Panel | Industrial-grade PLC with touch screen interface |

| Safety Guard | Transparent acrylic/polycarbonate for visibility and protection |

L-Bar Sealer Benefits

| Benefit | Description |

| Consistent Sealing | Smooth, firm, and uniform sealing lines improve product presentation |

| Reduced Labor Costs | Automation minimizes manual intervention on production lines |

| Flexible Packaging | Adjustable sealing area handles various product shapes and sizes |

| Energy Efficient | Optimized heating reduces power consumption by up to 27% |

| Low Maintenance | Durable components and a simple design reduce downtime and maintenance costs |

L-Bar Sealer Optional Upgrades

| Upgrade Option | Description | Customer Value |

| Servo Motor Control | Higher precision and speed for film feeding and sealing | Increased throughput for high-volume operations |

| Anti-Static Film Feeder | Reduces static during packaging of electronic products | Protects sensitive components and improves safety |

| Stainless Steel Version | For food, pharmaceutical, and hygiene-compliant production | Meets strict hygiene standards and easy cleaning |

| Adjustable Work Table | Suitable for tall or irregularly shaped products | Flexible operation for diverse packaging needs |

| Integrated Labeling or Date Printing | Adds automated labeling or coding | Streamlines packaging and meets regulatory requirements |